From plastic to fantastic

How buying recycled has helped to build an industry

by Alison Hill

There’s so much good news about single-use plastics around as Plastic Free July winds up: Coles will no longer sell collectible toys or single-use plastic tableware and governments across the country are stepping up to ban problematic single-use plastics. We’re building a brighter future for our kids with Lego planning to make blocks from recycled plastic bottles.

Steering clear of plastic may be the best way to step up, but as anybody who’s tried to entirely avoid it knows, it’s almost impossible to completely steer clear of plastic packaging. Recycling plastics whenever we can makes a huge difference. Buying things made from recycled plastic closes the loop.

Recycling sometimes gets a bad rap, being as it is at the bottom of the refuse, reduce, reuse, repurpose, recycle hierarchy of waste reduction. But plastic waste can be recycled relatively easily into useful and even beautiful new products. Using recycled plastic uses far less energy and emits far less CO2 than using new plastics. It also doesn’t use oil as virgin plastics do. And perhaps most importantly, it cuts down on the amount of plastic that is dumped into landfill, or ending up in oceans and waterways.

Instead of seeing plastic as waste to be thrown “away”, we can start to see it as a precious and useful resource. And as consumers, we can make a difference by driving demand for recycled products. So let’s go shopping!

How does plastic recycling work?

First, put your plastic bottles into the home recycling bin or, better still, take them to a container deposit scheme collection point where they will be pre-sorted. You can even earn some spare cash or donate to a community cause when you drop off your eligible containers. Then they’re collected and transported to a purpose-built sorting facility and sorted into different types of plastic. The sorted plastics are packed into bales and sent on to a recycling facility. Here the plastics that can be made into new products are washed, shredded into flakes and then melted. The melted plastic is put though a machine that turns it into pellets, ready to make new items. To be made into fabrics, the pellets are melted and spun into yarn.

At the very practical end of the spectrum, recycled plastic is made into wheelie bins, street furniture, garden edgings and new plastic bottles. More exciting for most of us, though, is that recycled plastic is an ideal material for making sportswear, polar fleece clothing, throws and rugs, dog collars and even wetsuits.

Let’s meet one brand and two women, who started small and are set to make a big difference.

Activewear brand MAD Active was launched only a year ago by Madison Pallotta and Jayme Chittenden in Melbourne. They wanted to make sustainable, affordable, good-looking activewear. But needing to create a brand that matched their desire to be ethical and sustainable took them a few years. “We wanted to feel we were making a difference to the world each time a purchase is made”, explains Madison. “It took two years to find a manufacturer that I was happy with. I think Coronavirus lockdown actually helped me put in the time that it needed”, she says.

They chose a manufacturer in Bali who makes the fabric for their shorts, leggings and crop tops from recycled PET bottles. The bottles are all picked up from the beaches and streets of Bali too, helping to deal with the island’s plastic waste problem.

“They’re cleaning up the ocean. There’s so much plastic on the beaches because there isn't recycling like we have in Australia. It just ends up in landfill or into the ocean.” Each pair of MAD Active leggings reuses about six plastic bottles, and each crop top about five.

“I just hope people can see that they can make a difference with their purchases, in creating demand, because each decision to buy recycled and sustainably creates demand,” says Madison.

MAD Active follow through by using people to sew the final garments who are paid above minimum wages, as part of the #whomademyclothes movement.

Each order is packed into a reusable bag that is great to wash the leggings and crops in. They use compostable mailing bags, and orders are delivered by carbon-neutral delivery service Sendle. And $1 from every purchase is donated to Save-A-Dog Scheme.

What’s not to love?

(And yes - of course, every time we do laundry, our clothes (whether they're made from recycled materials or not) shed tiny microfibres, which go down the drains of our washing machines, through wastewater treatment facilities and into our waterways. The solution? A Guppyfriend Wash Bag or a Cora Ball (pictured below: made from 100% recycled and 100% recyclable soft and stretchy plastic) which swooshes around in the washing machine and just like coral, allows water to flow, while picking up those little pieces of microfibres and catching them in her stalks)

For more innovative and useful products made from recycled plastic, take a look at these:

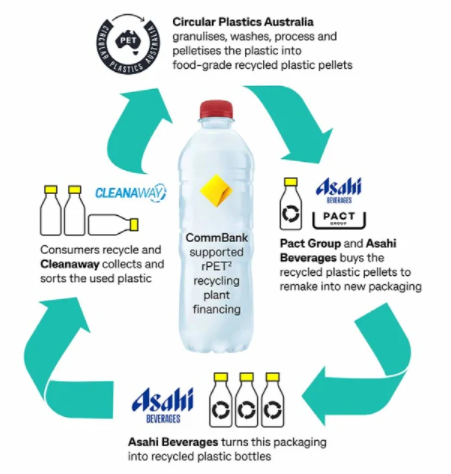

At the moment, Australia has only one PET recycling plant. But happily another is under construction in Albury-Wodonga and is expected to be operational later this year. Circular Plastics Australia (CPA), is a partnership between waste collector Cleanaway, packaging producer Pact Group and drinks company Asahi Beverage and will be Australia’s largest PET plastic recycling plant and only the second facility of its kind in Australia to process PET end-to-end into food-grade recycled PET.

The facility will draw on the expertise of each member of the joint venture: Cleanaway will provide the plastic feedstock from its collection and sorting network, Pact will provide technical and packaging expertise while Asahi Beverages and Pact will buy the recycled plastic from the facility to use in their packaging.

The facility is anticipated to recycle approximately 1 billion PET plastic bottles each year, reducing Australia’s reliance on virgin plastic, the amount of plastic waste sent overseas and the amount of recycled plastic Australia imports. The production of more than 20,000 tonnes of new recycled PET bottles and food packaging will increase the amount of locally sourced and recycled PET produced in Australia by two thirds – from around 30,000 tonnes currently to over 50,000 tonnes annually, according to Pact Group.

Illustrating how important consumer demand is in bringing about change, Sanjay Dayal, CEO of Pact Group, a partner in the project with Cleanaway and Asahi, said at the start of the plant’s construction: “This project would not have been possible without increased demand for locally processed recycled content from forward-thinking companies who are keen to meet Australia’s 2025 National Packaging Targets.”

Alison Hill writes features and web copy from the Blue Mountains west of Sydney.

Search for other blog topics: