Elle Evans Swim and Activewear

The norm in fashion is to manufacture as much as you can all at once in order to reduce costs. We decided the better way for us to manufacture would be to make each swimsuit, legging or sports-bra only after someone had purchased it. That way we know each Elle Evans piece we make is going to a happy home, not to landfill.

RECYCLED CONTENT DESCRIPTION (self-declared)

The ECONYL® process starts with the rescued waste, like fishing nets, fabric scraps, carpet flooring and industrial plastic from landfills and oceans all over the world. That waste is then sorted and cleaned to recover all of the nylon possible. Through a radical regeneration and purification process, the nylon waste is recycled right back to its original quality -a process that is far less environmentally harmful that the production of “virgin” nylon.

That nylon fibre is then knit into our soft swim fabric in a mill in Italy, before it reaches our supplier in QLD. Our Aussie pinter digitally prints our fabric using water-based, non-toxic inks, no inks are discarded down drains and no washing is required after printing. They recycle all their discarded paper and they all fabric rolls despatched across the country are wrapped in recycled plastic

Cruelty-free

Ethical Production Practices

Compostable Packaging

Carbon neutral transport

-

Fashion and Activewear

Button -

Jewellery and Accessories

Button -

Kitchen and Food

Button -

Bathroom and Cosmetics

Button -

Laundry

Button -

Homewares and Furnishings

Button -

Sport and Recreation

Button -

Pet Products

Button -

Office and Stationery

Button -

Renovations and Flooring

Button -

Garden and Landscaping

Button -

Upcycled Art

Button

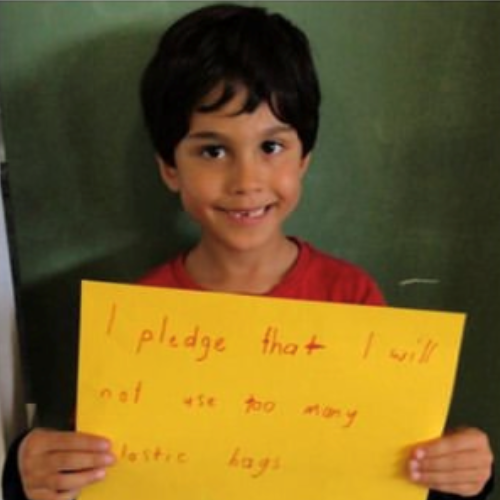

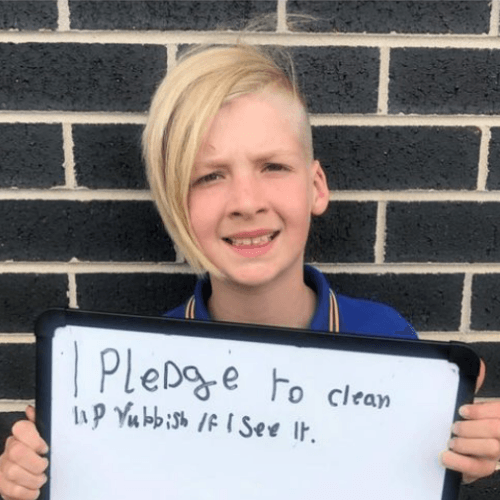

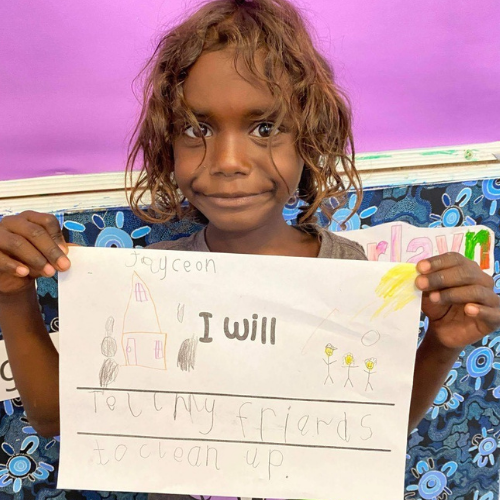

If you have any education or school-related enquiries, please contact our education team at education@cleanup.com.au

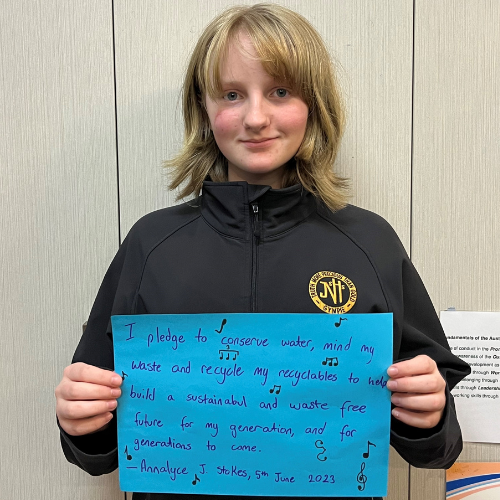

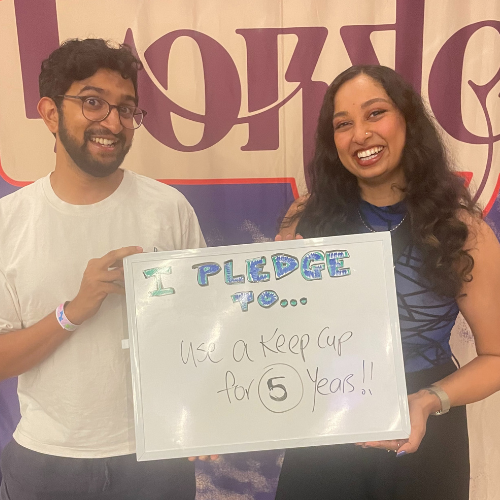

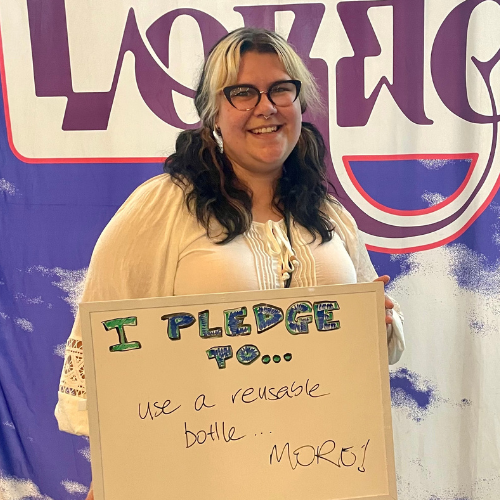

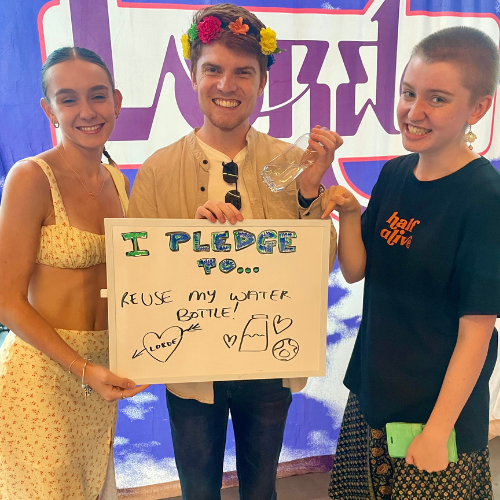

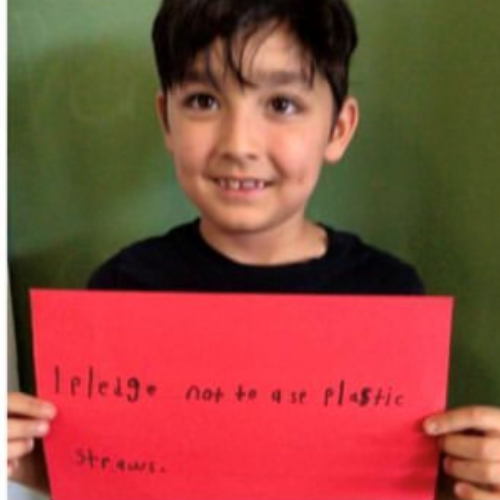

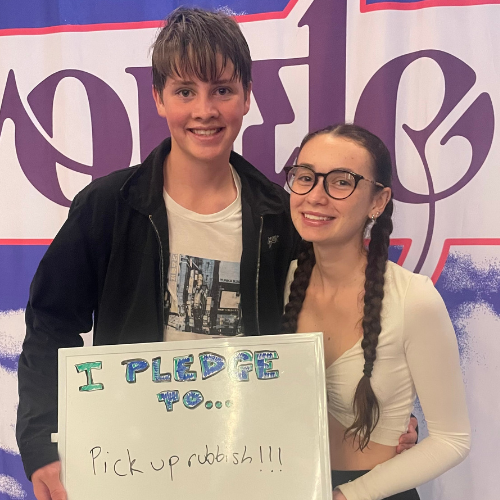

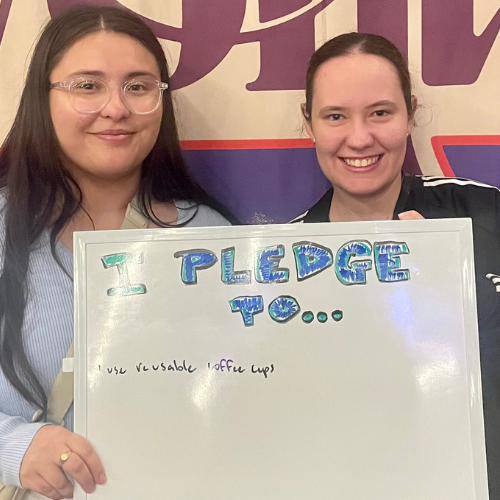

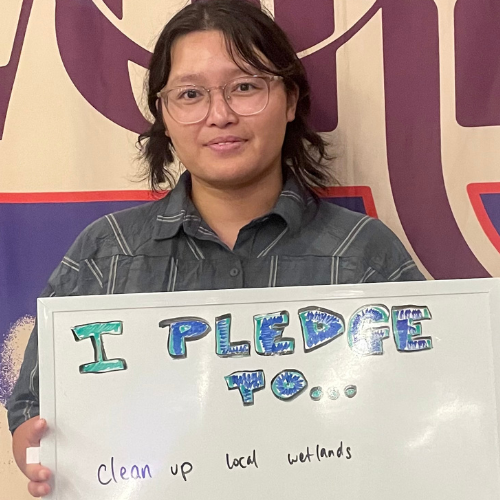

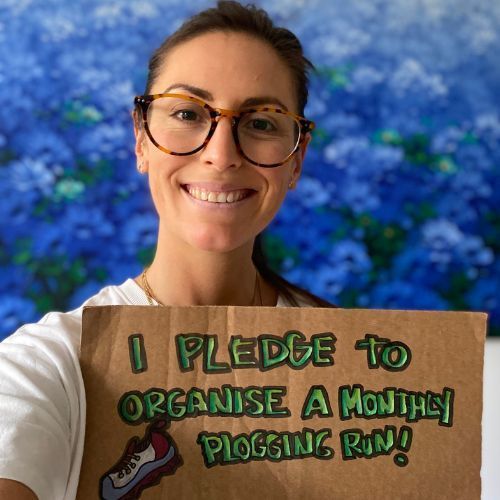

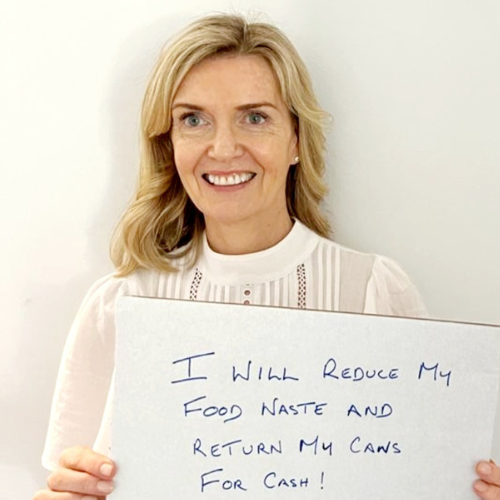

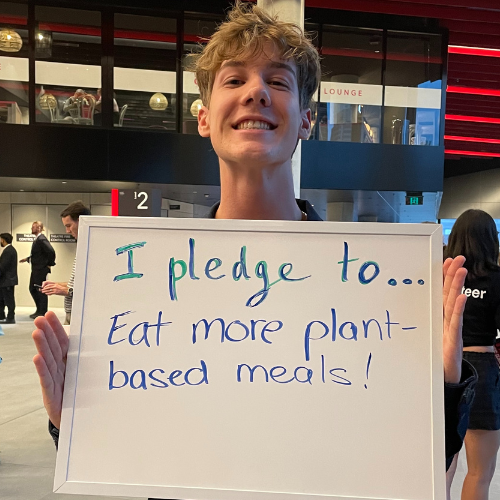

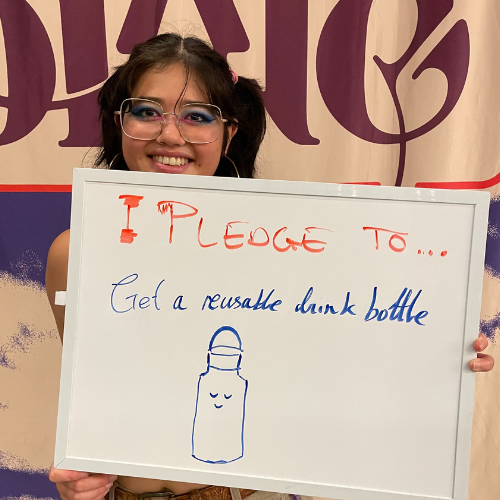

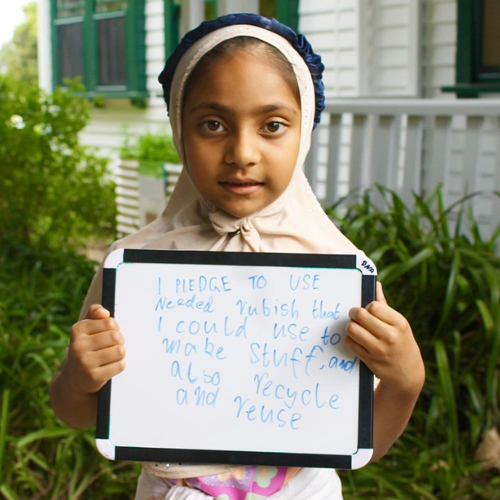

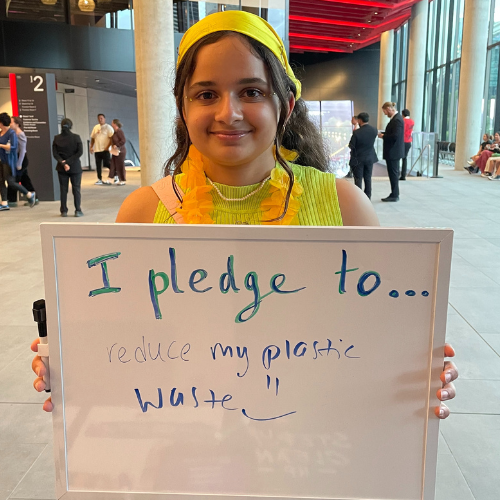

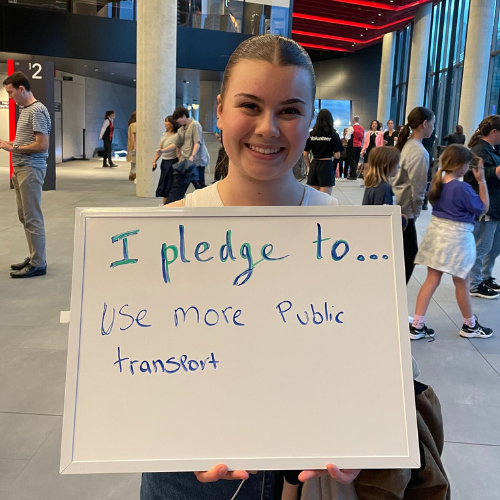

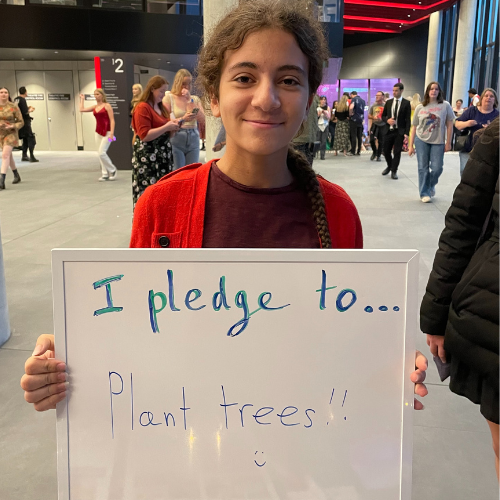

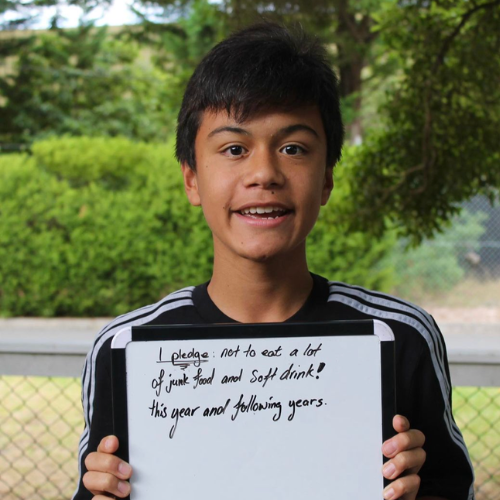

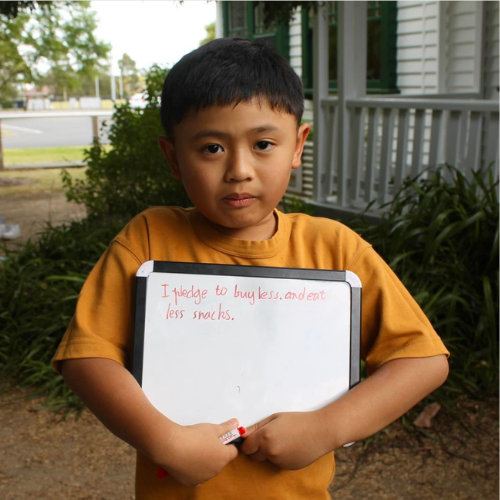

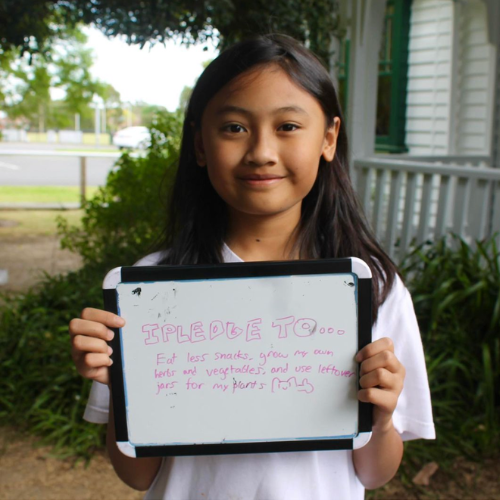

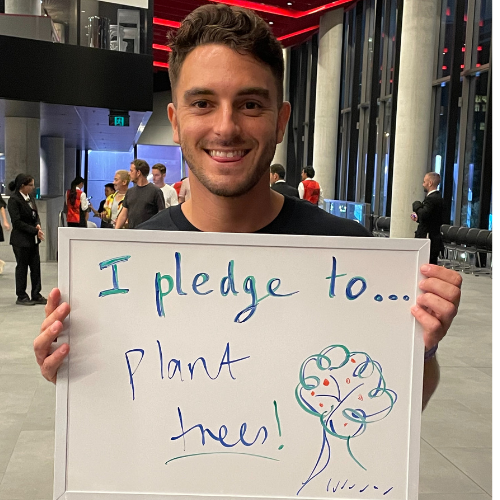

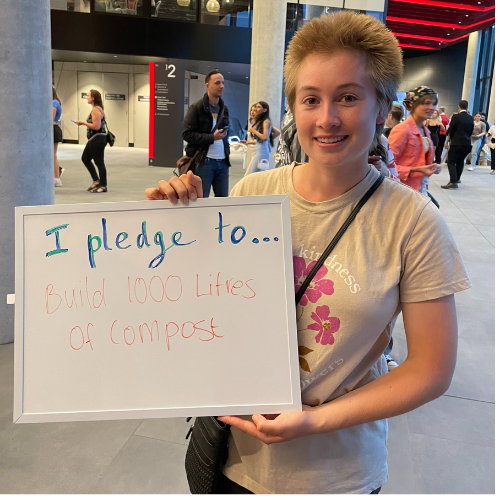

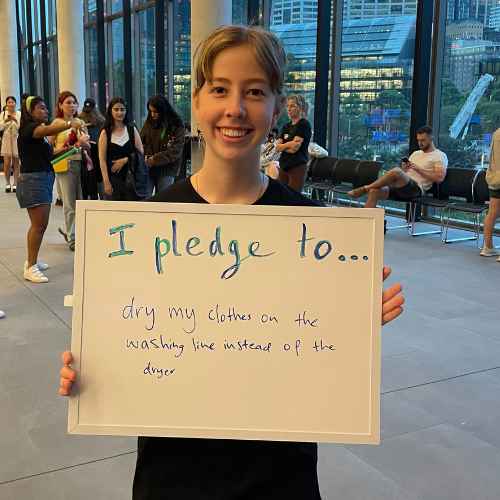

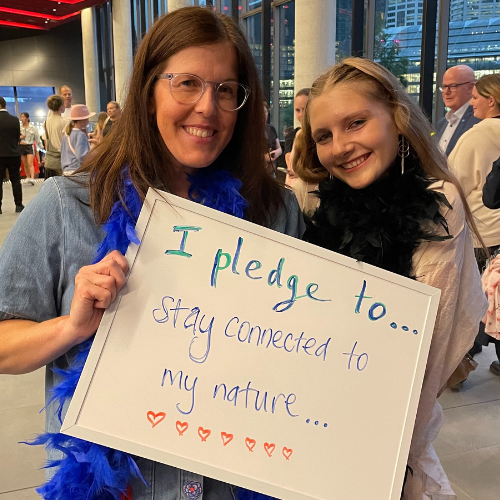

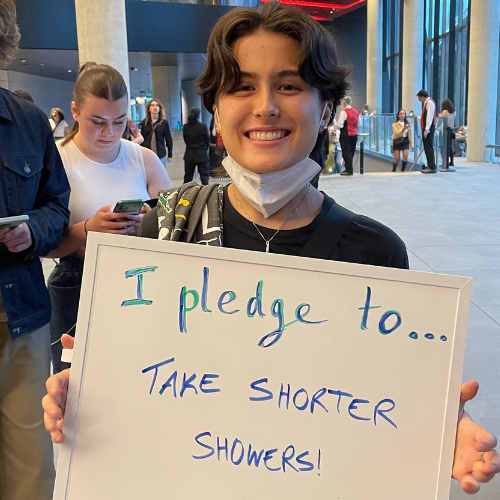

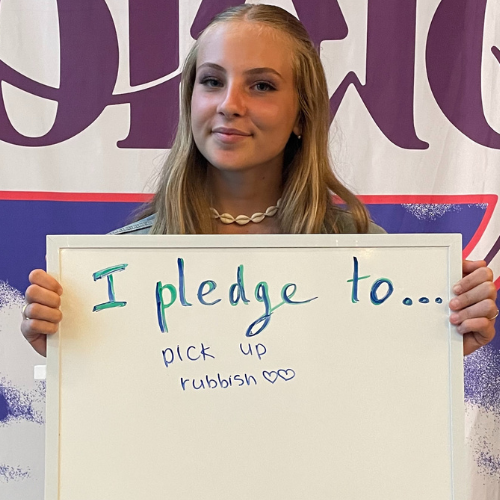

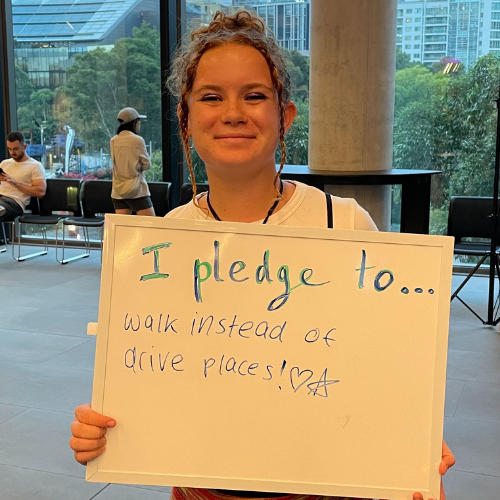

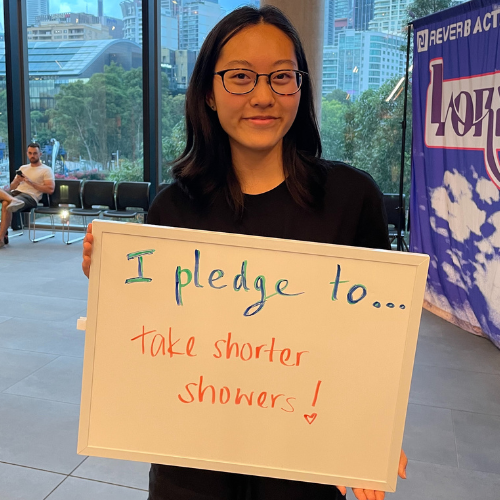

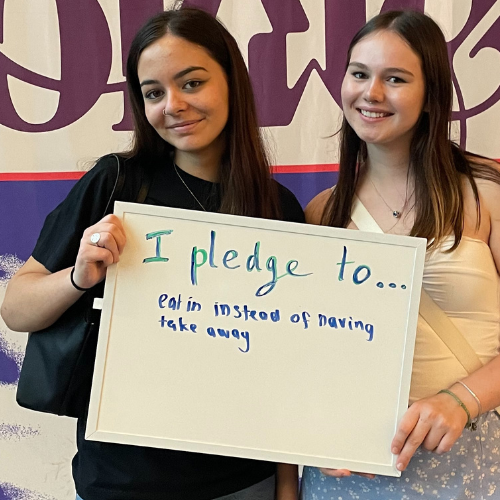

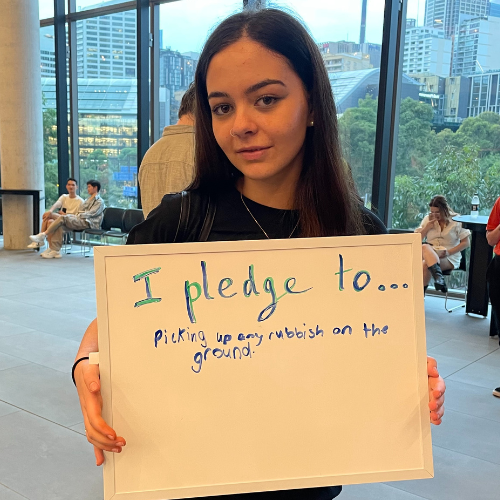

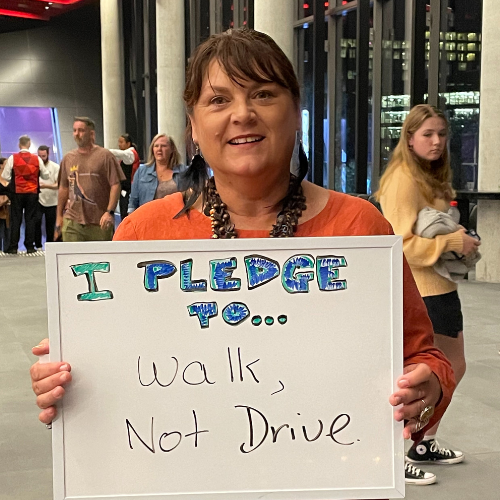

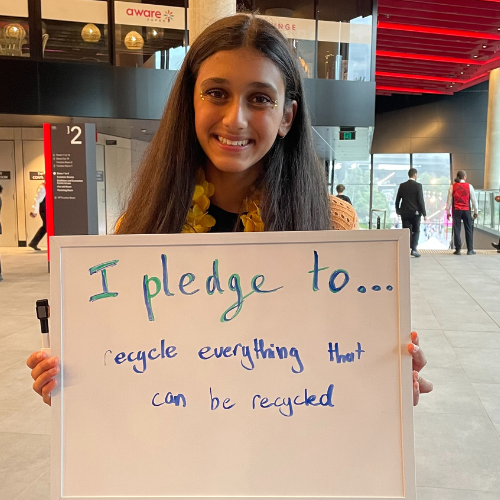

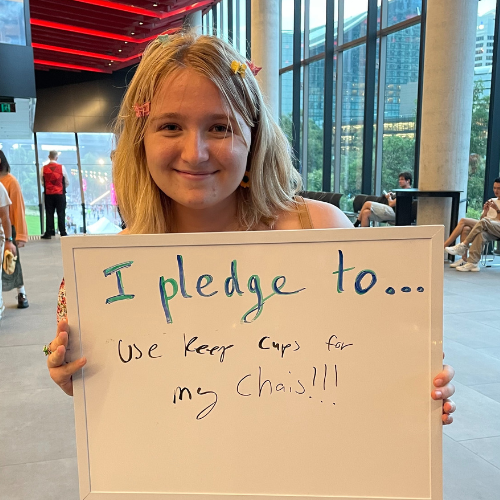

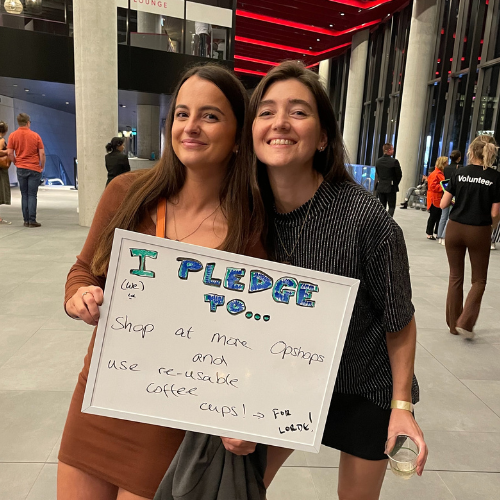

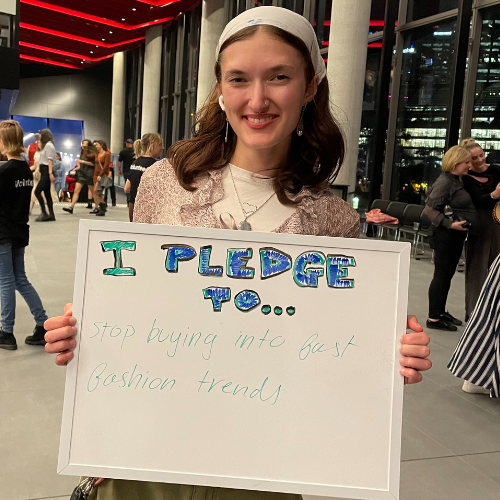

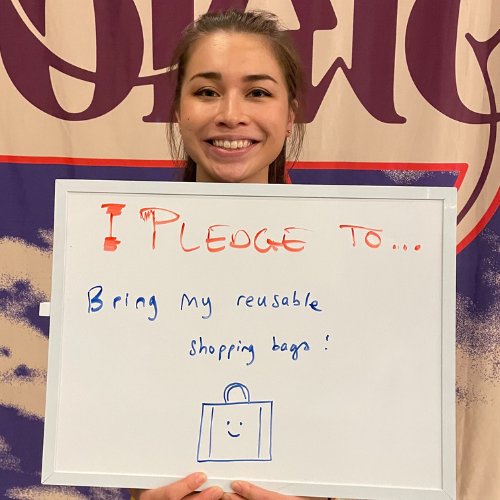

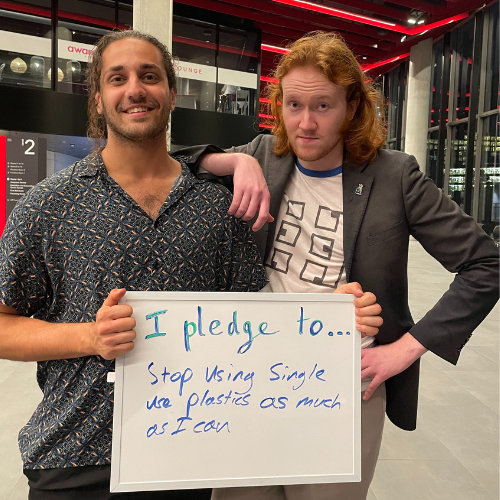

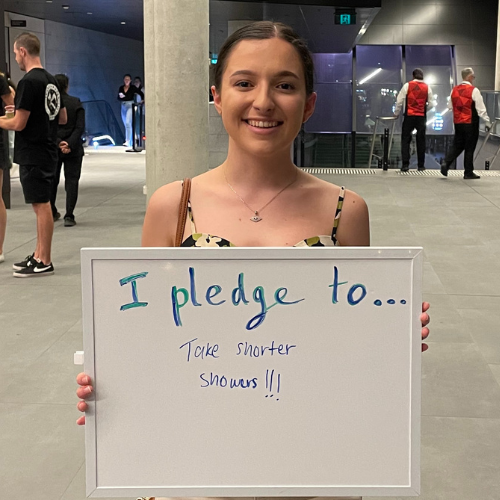

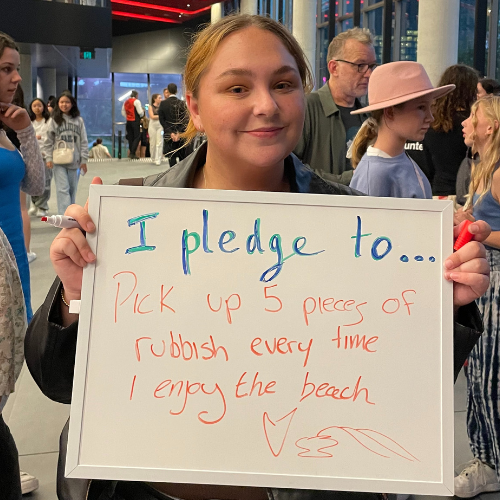

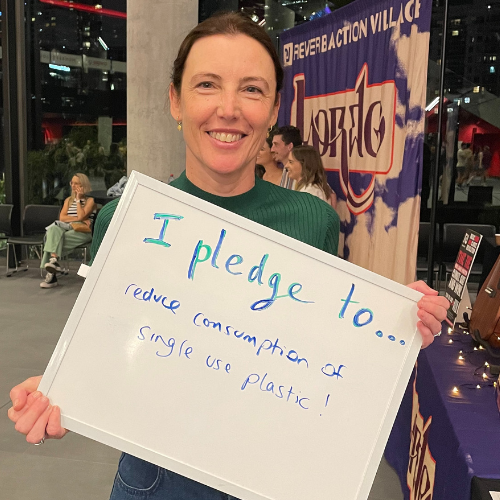

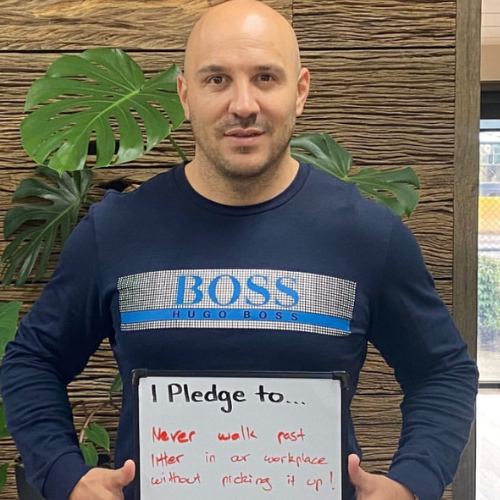

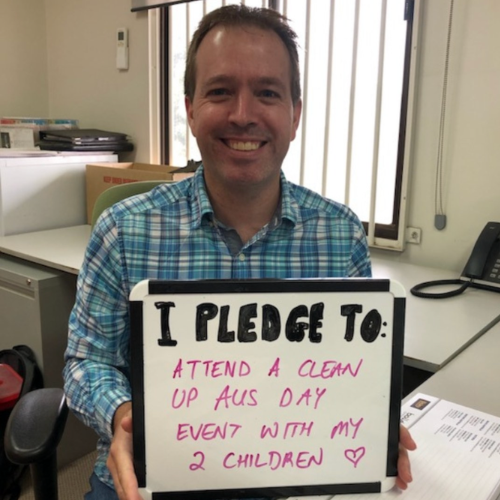

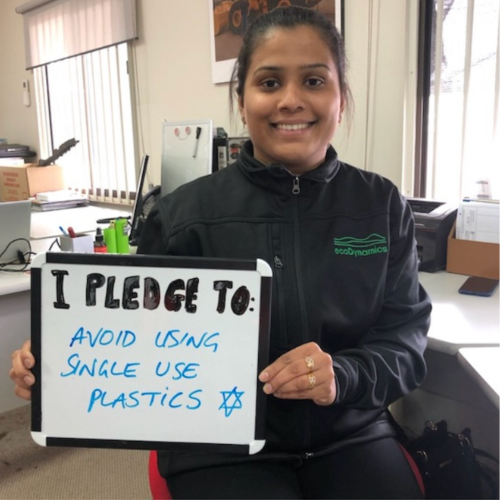

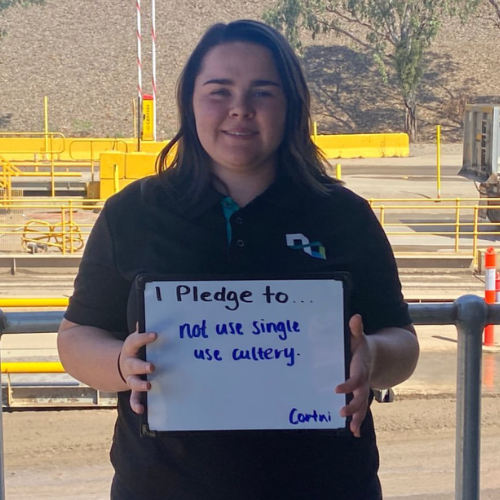

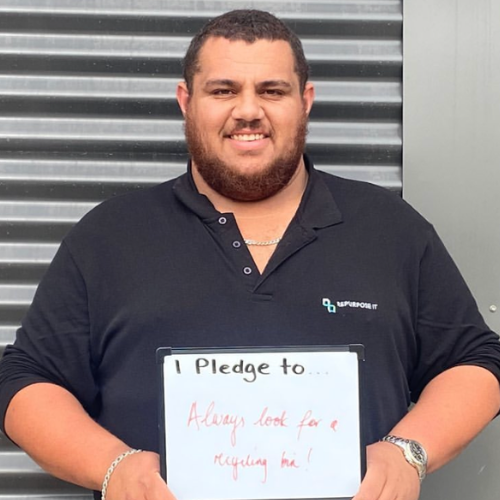

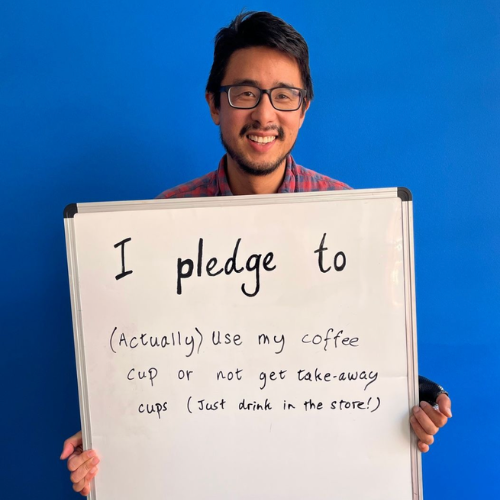

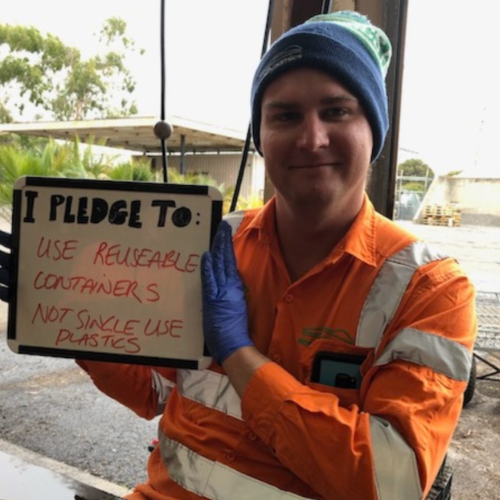

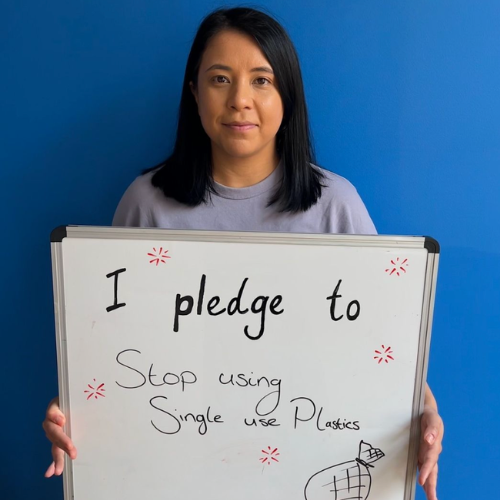

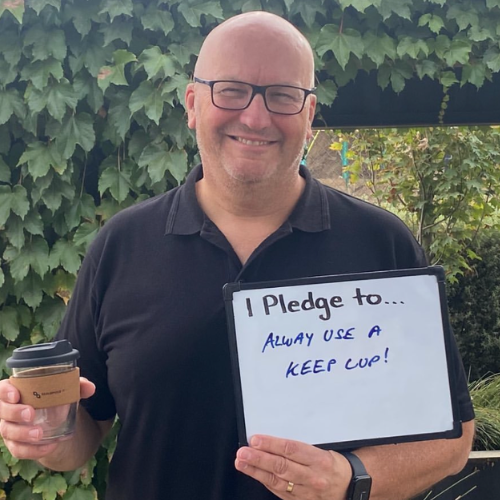

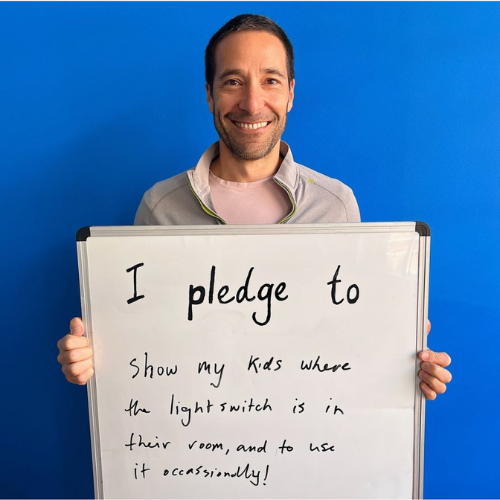

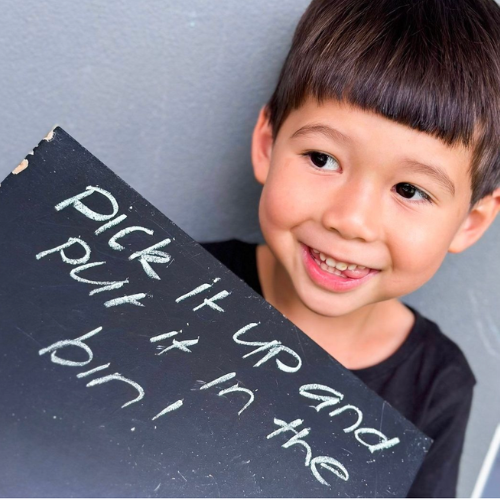

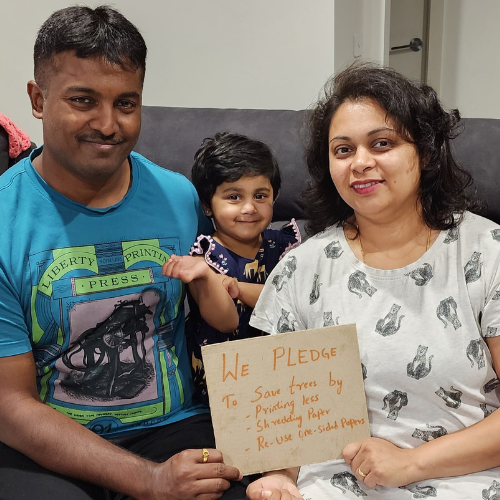

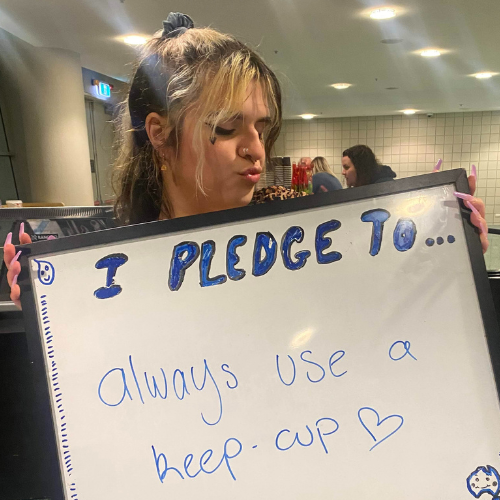

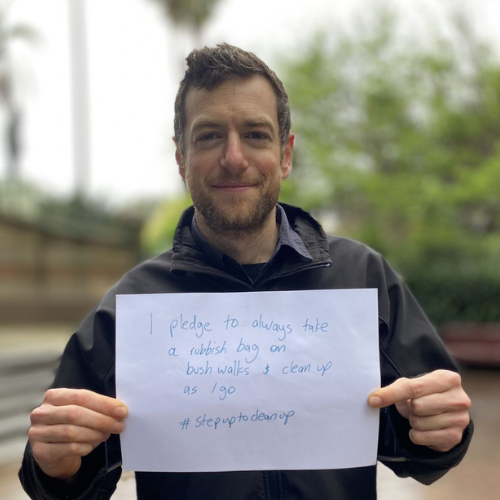

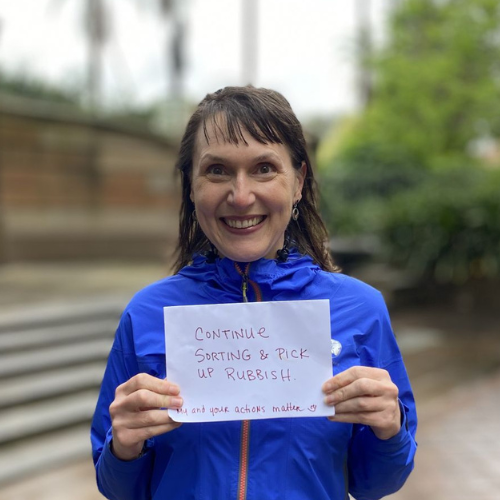

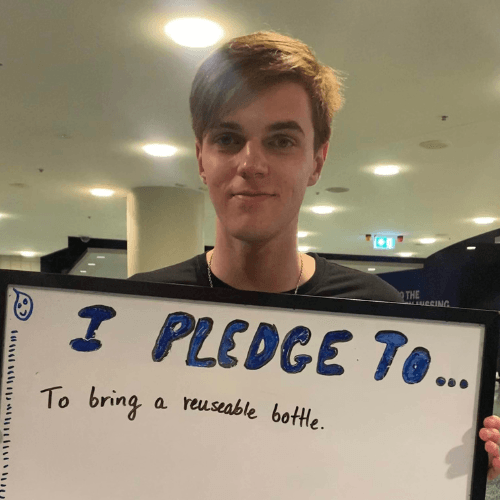

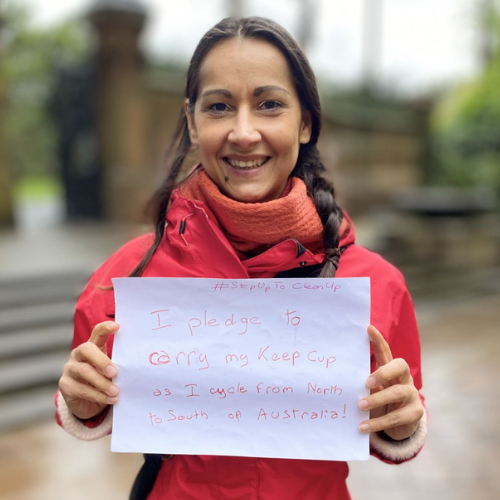

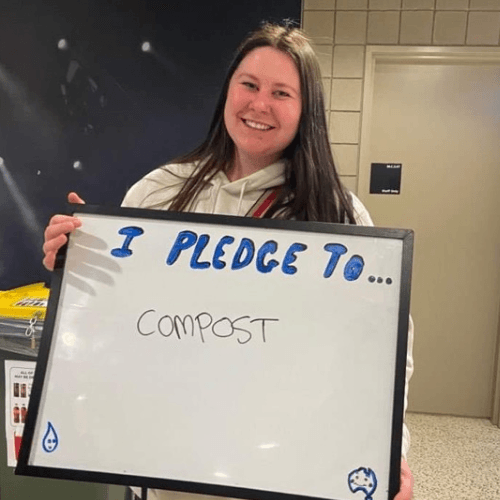

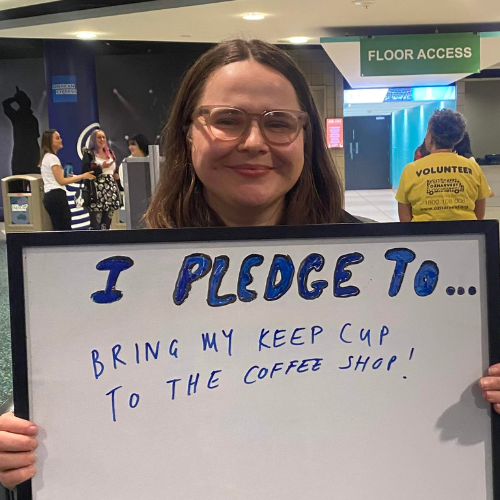

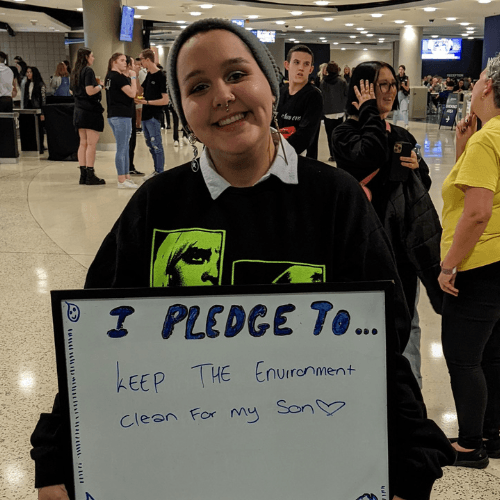

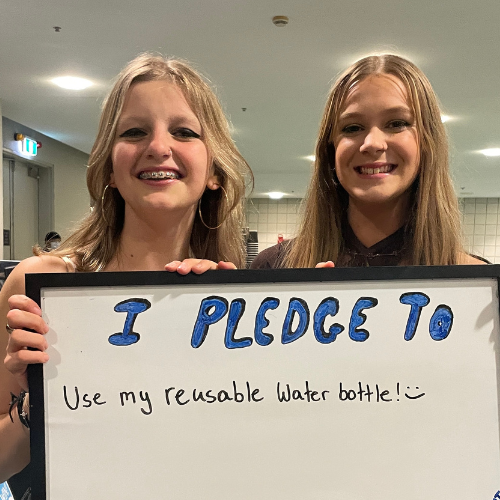

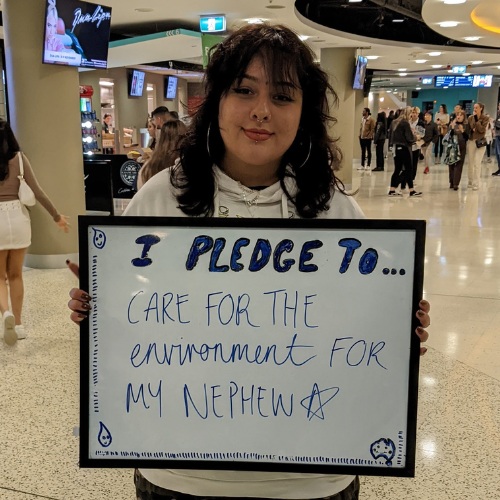

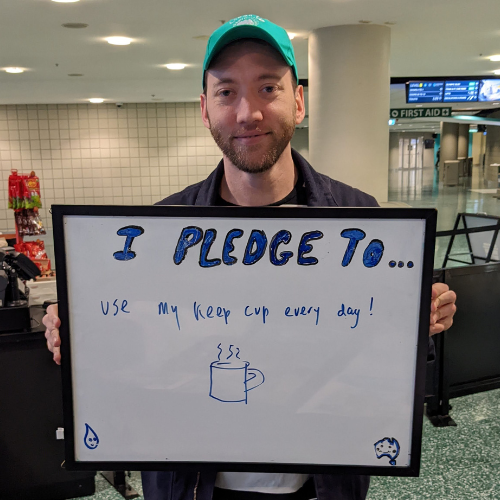

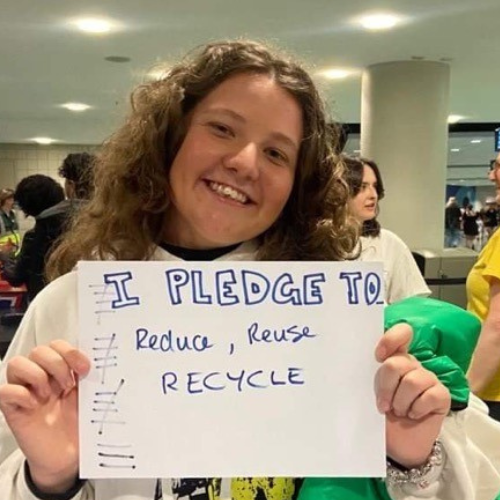

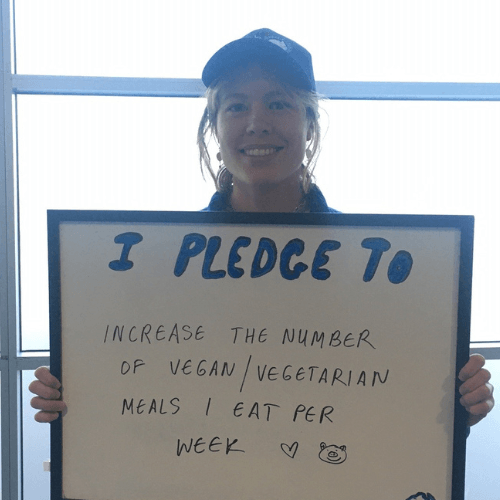

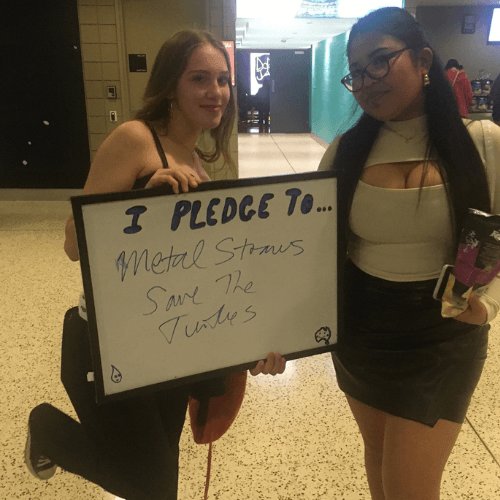

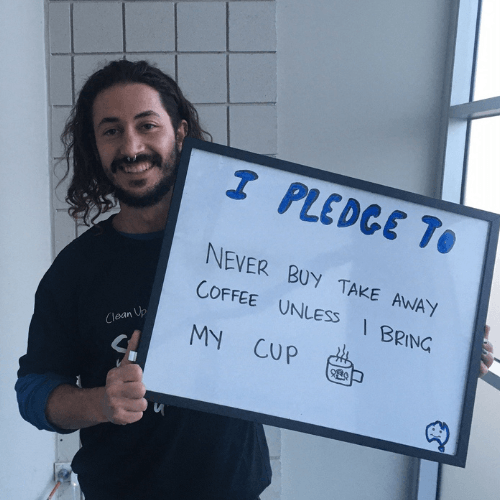

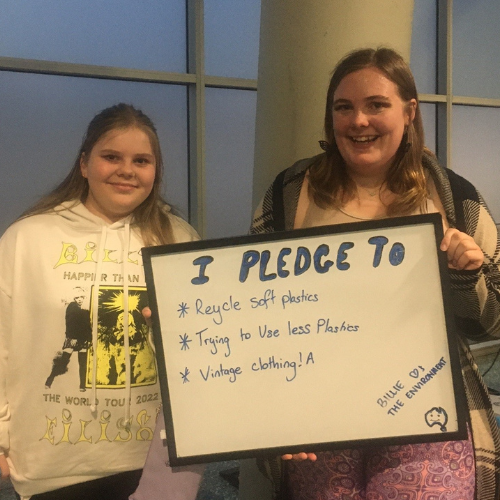

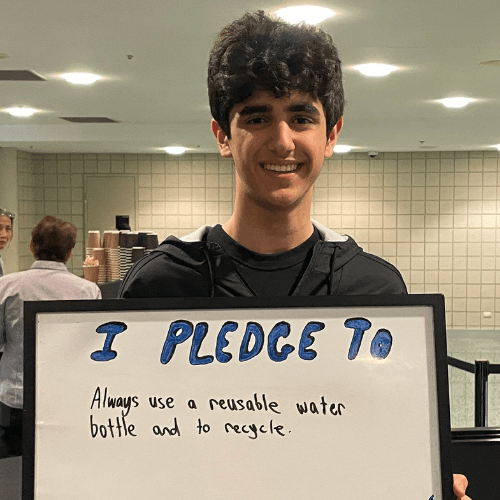

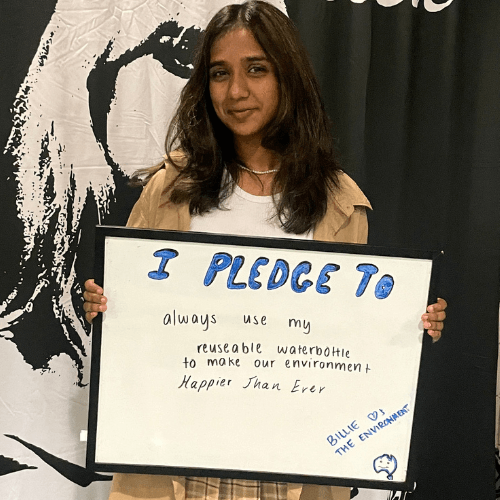

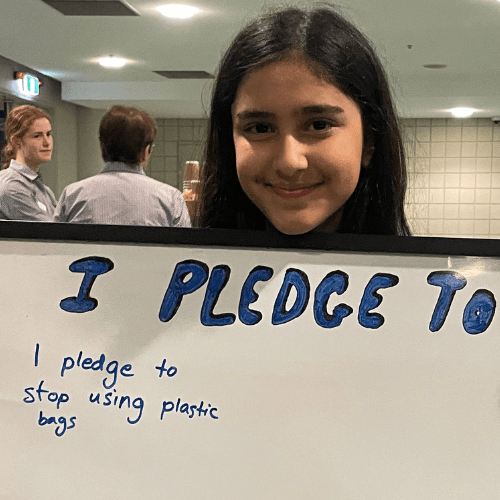

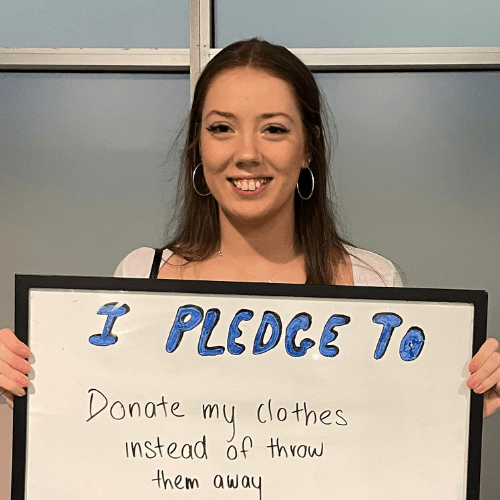

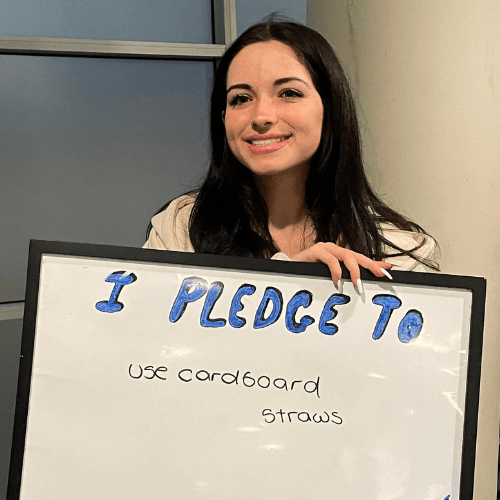

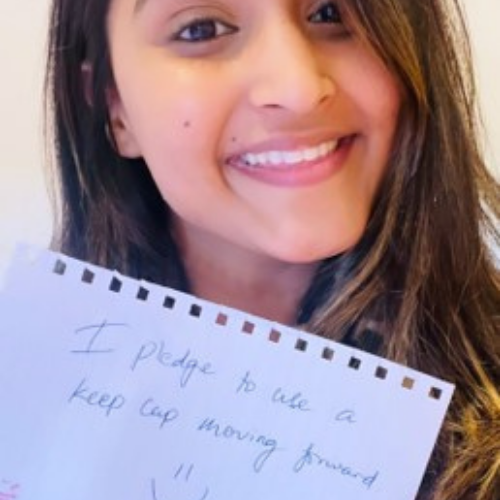

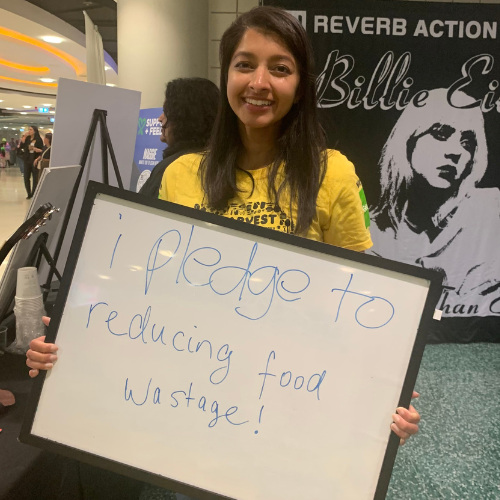

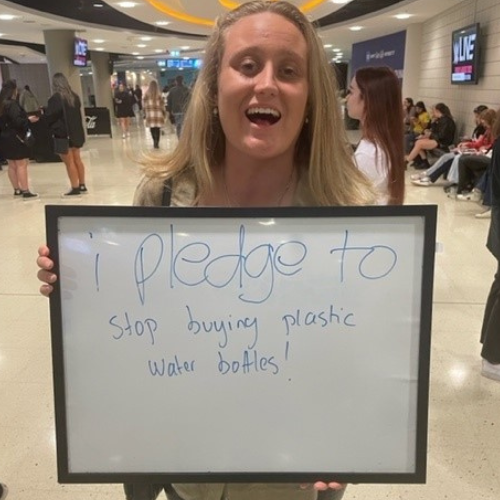

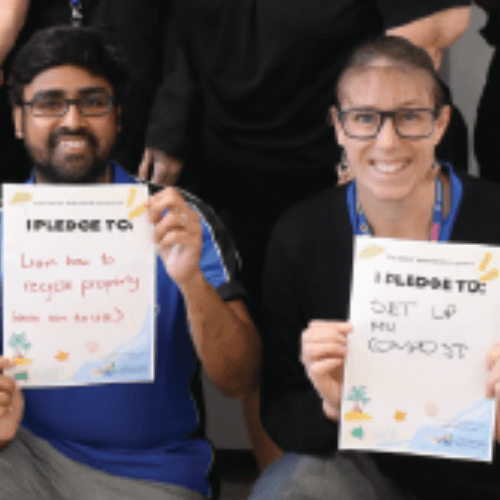

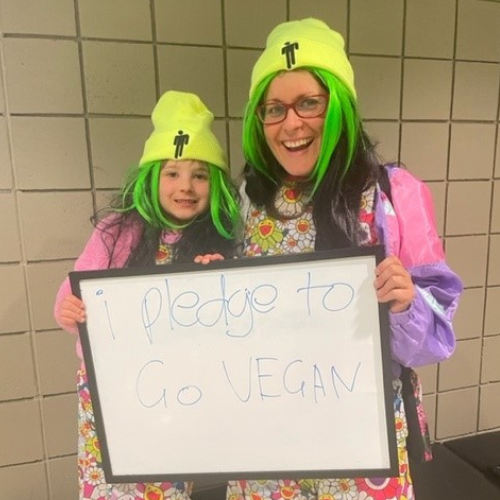

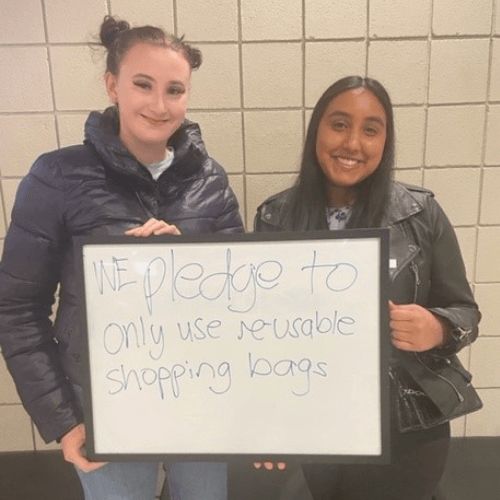

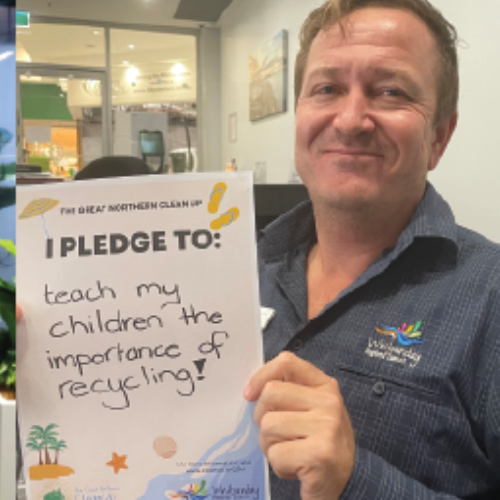

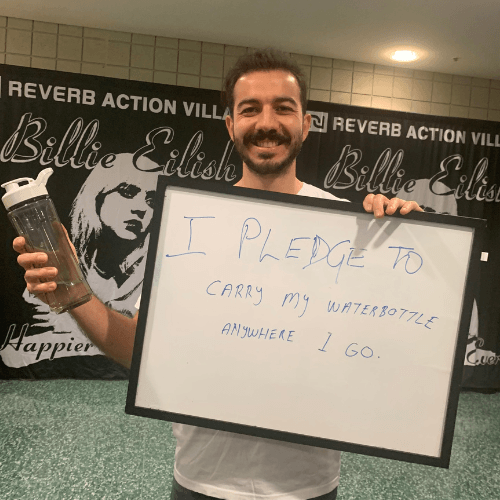

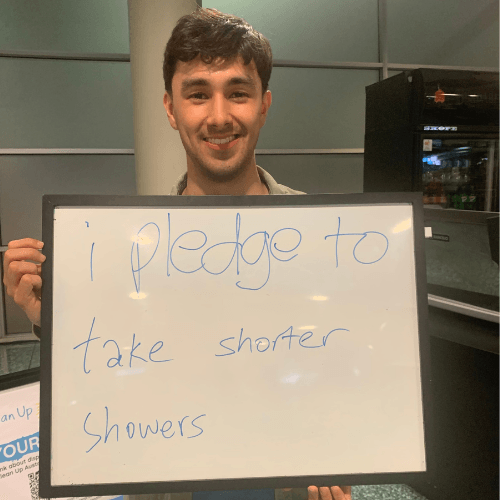

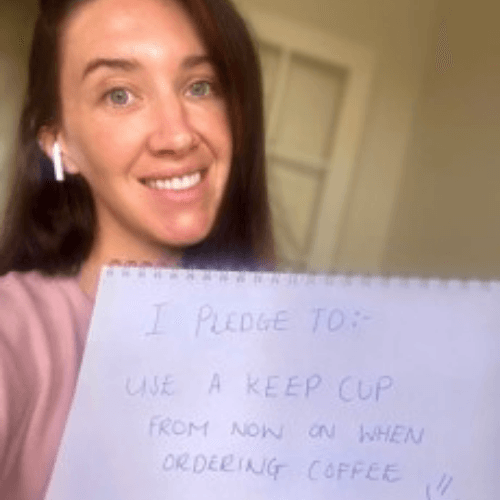

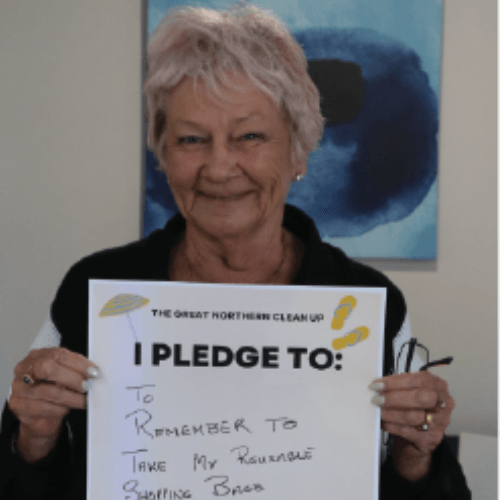

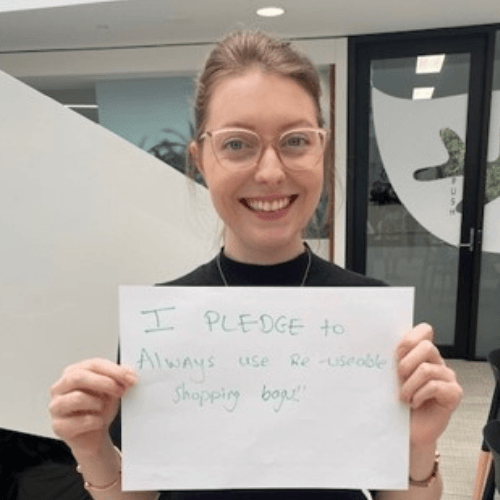

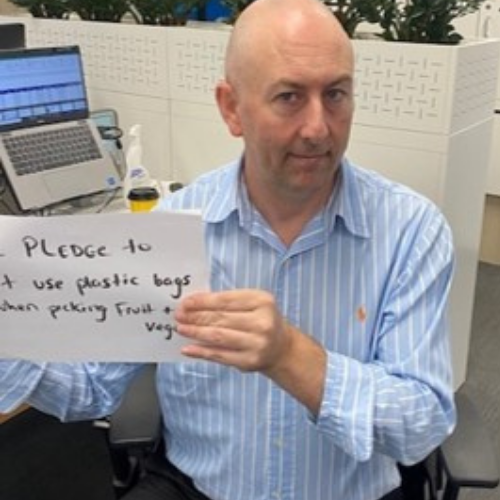

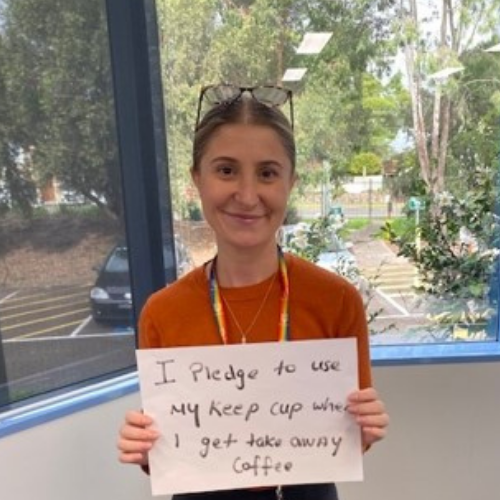

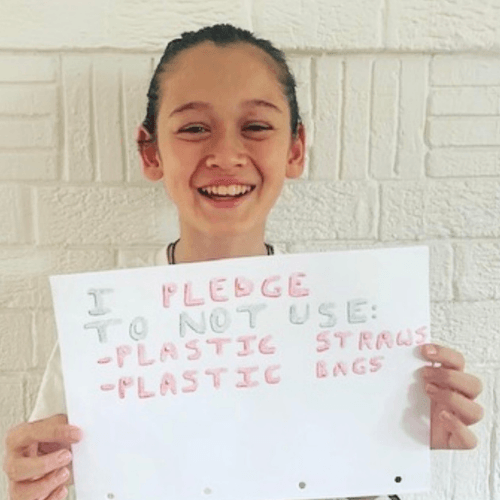

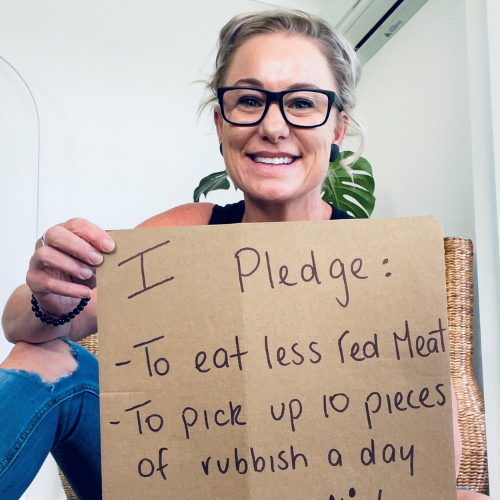

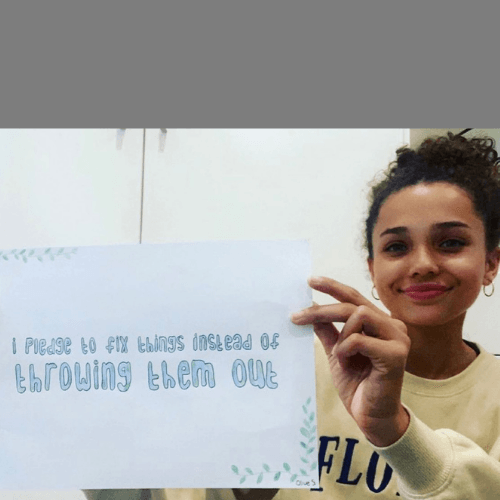

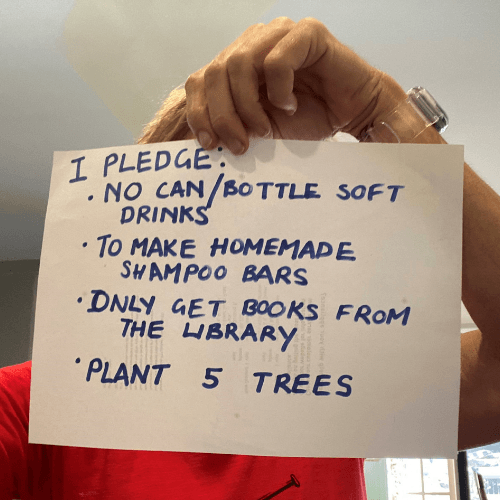

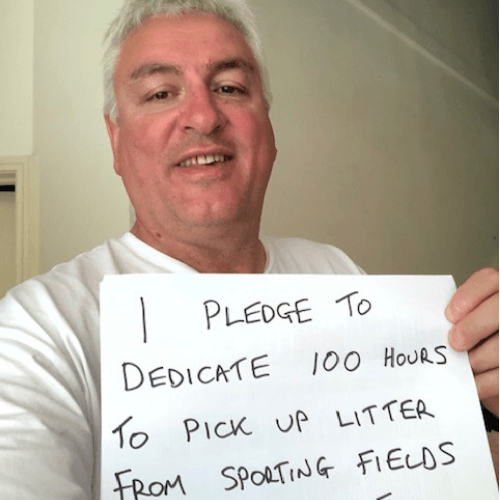

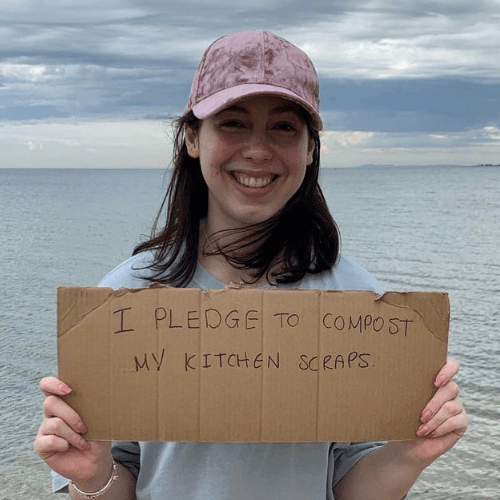

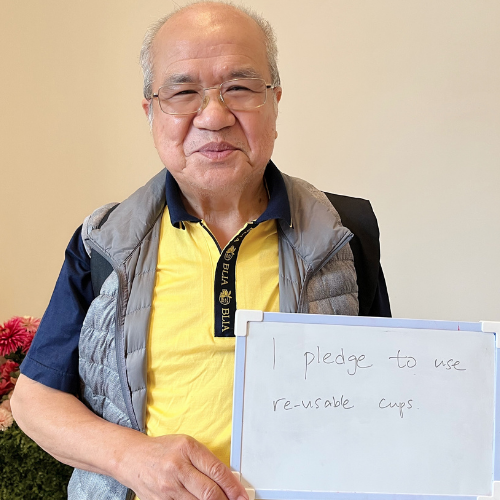

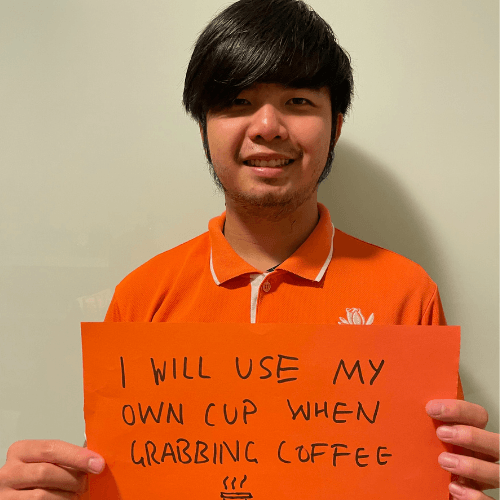

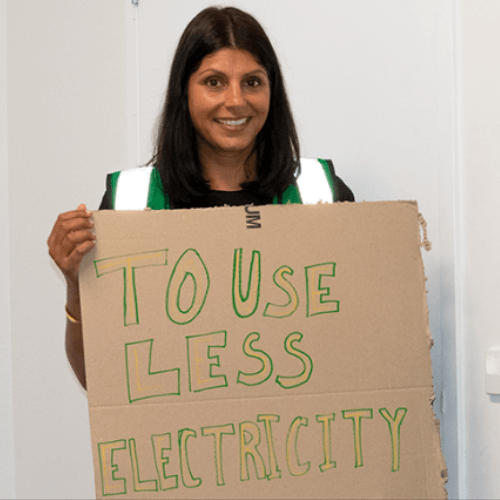

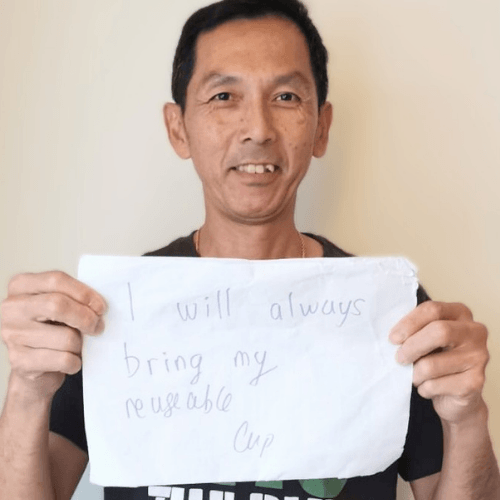

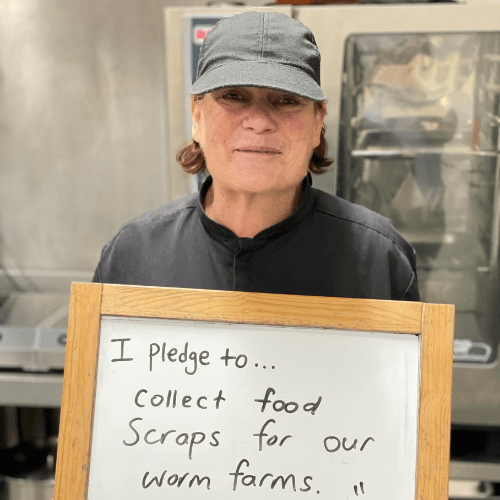

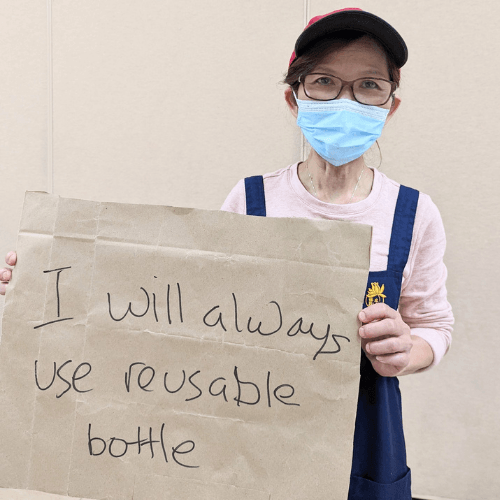

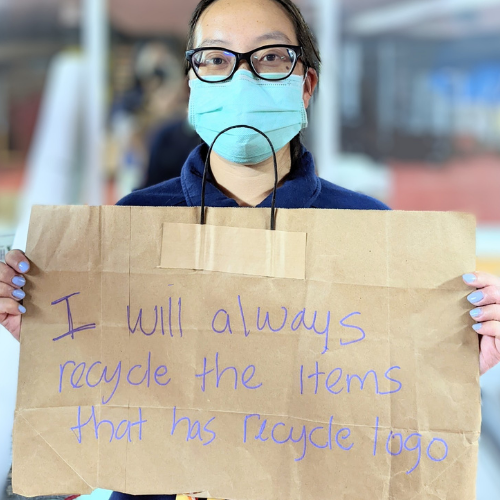

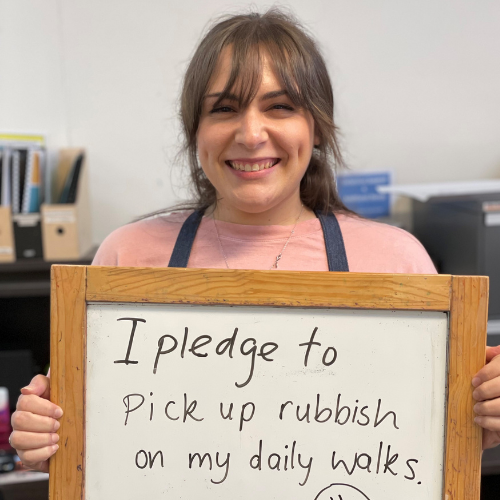

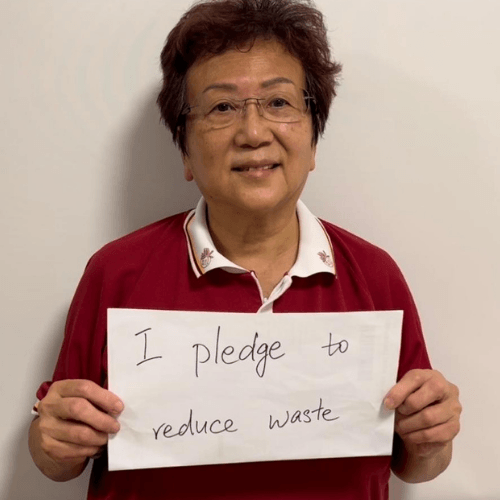

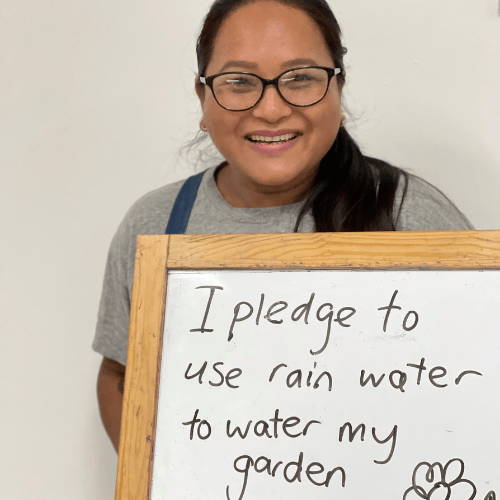

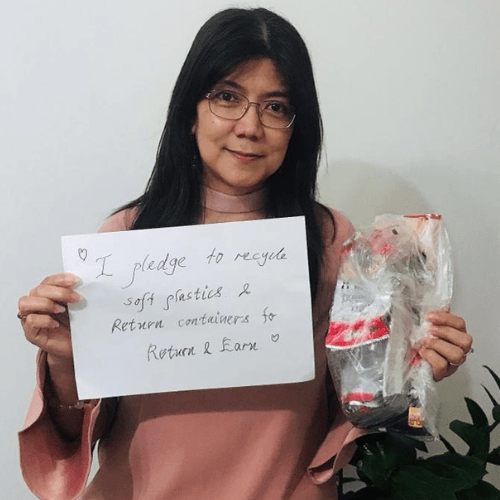

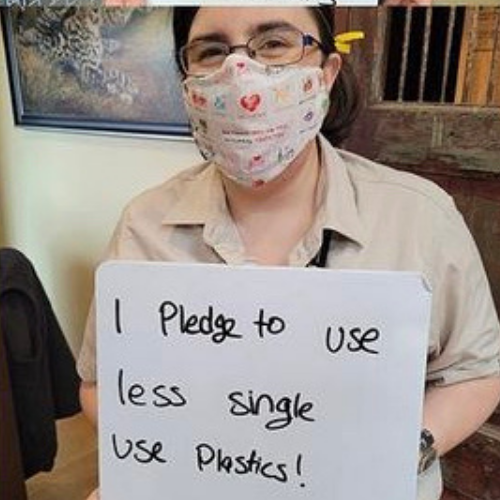

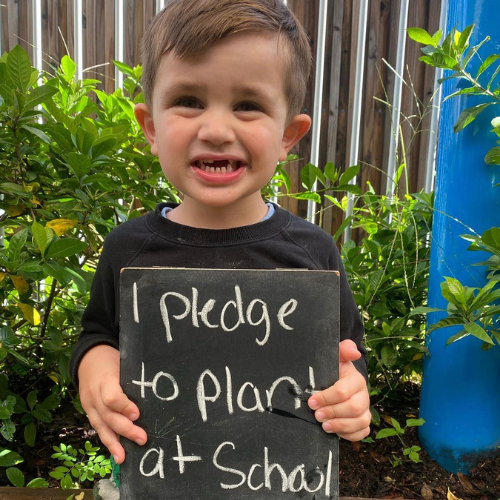

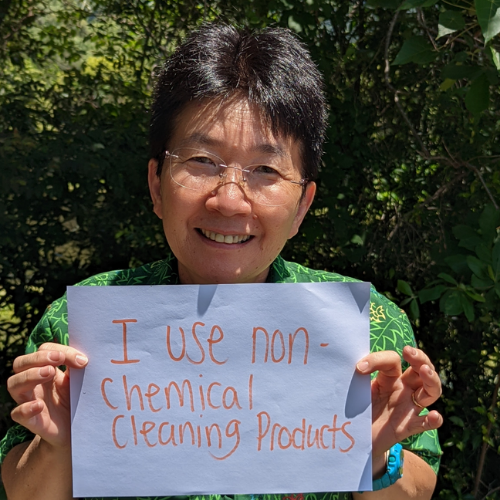

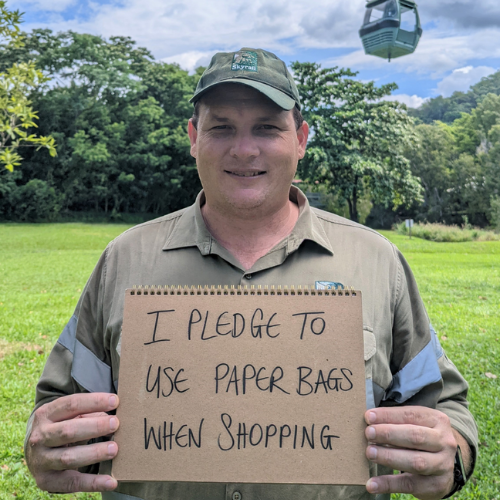

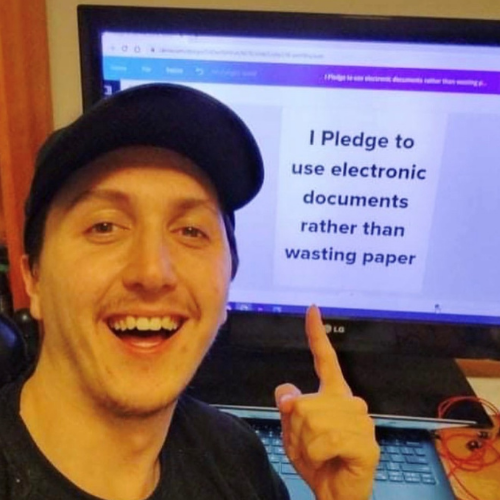

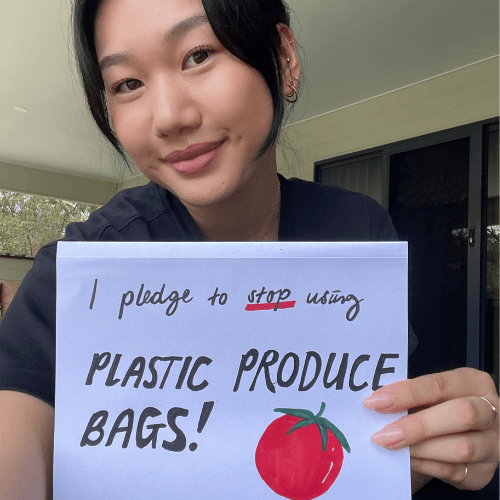

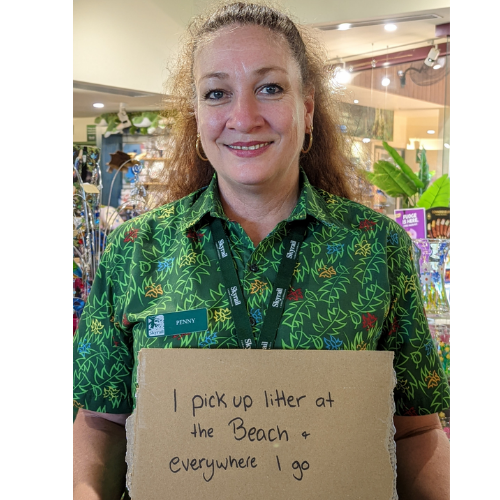

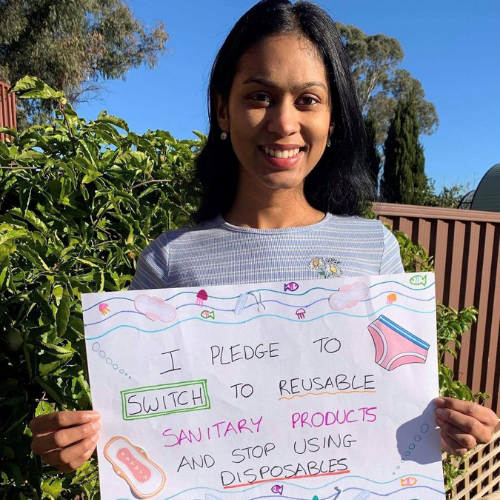

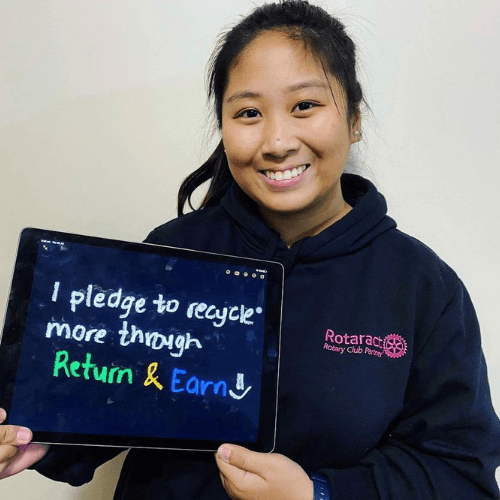

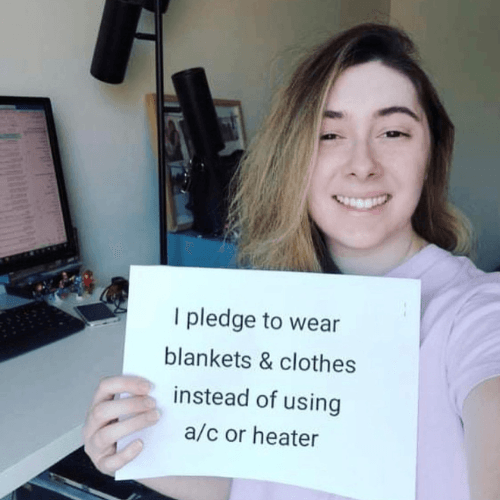

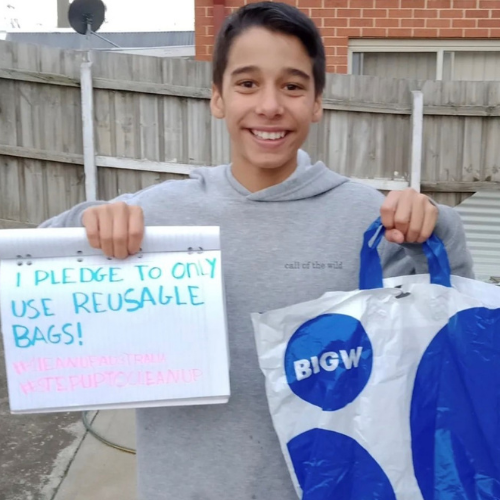

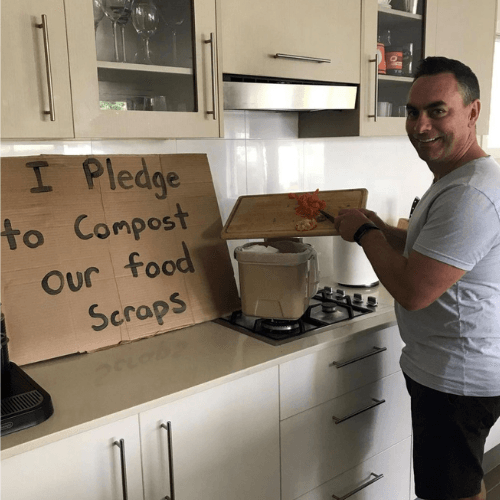

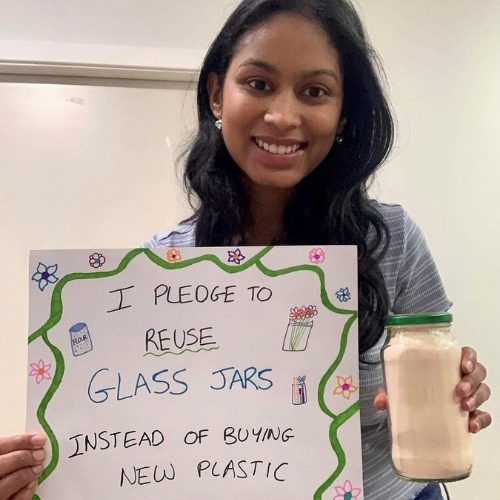

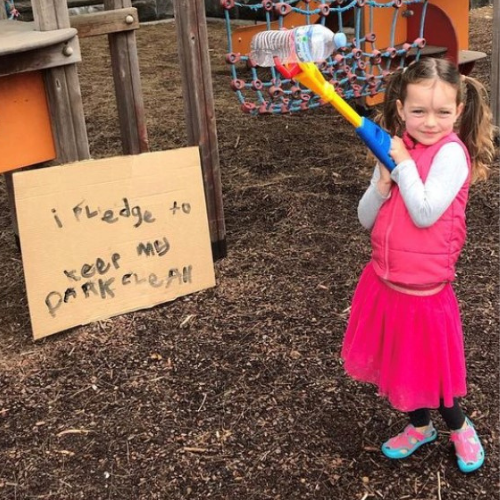

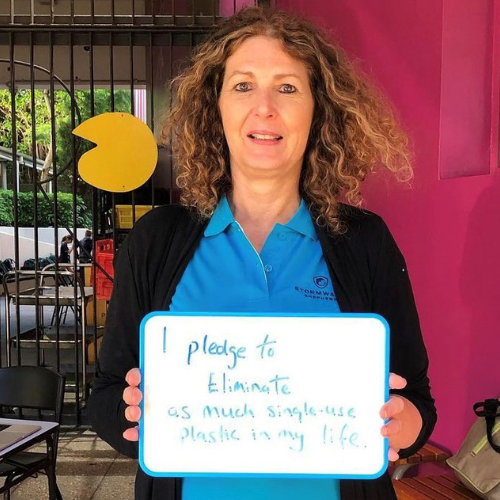

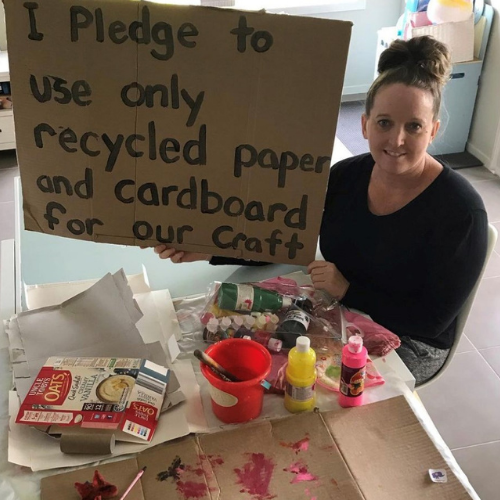

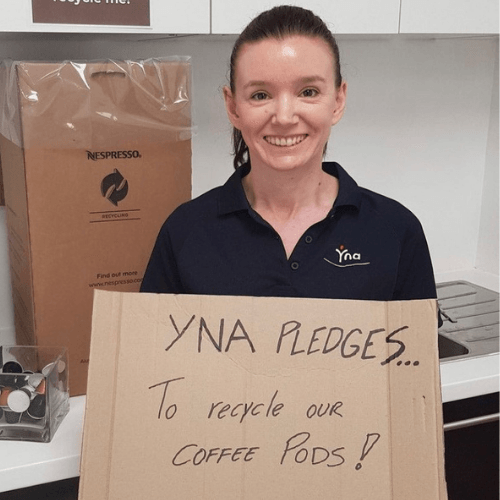

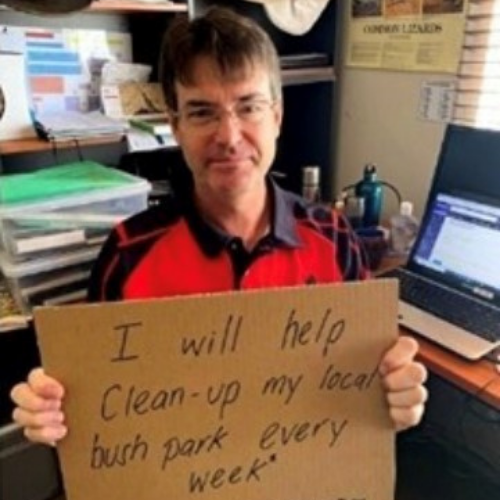

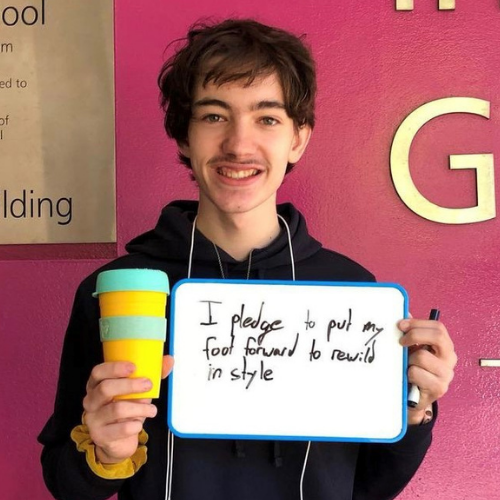

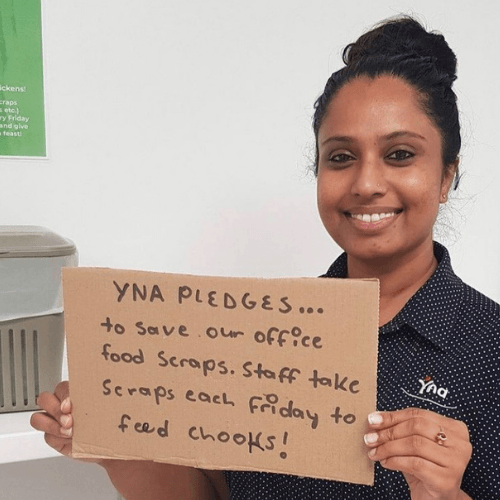

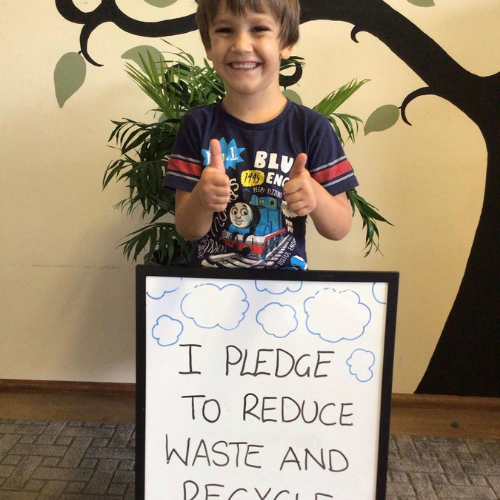

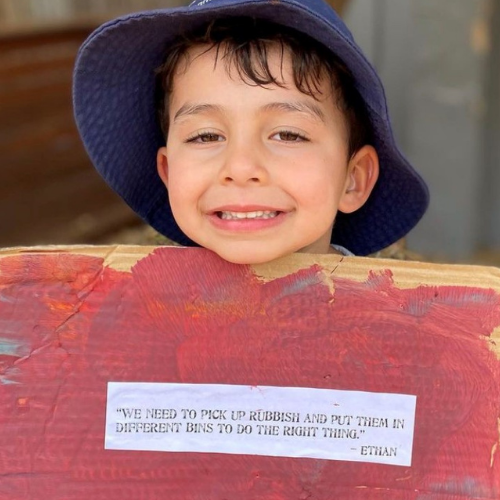

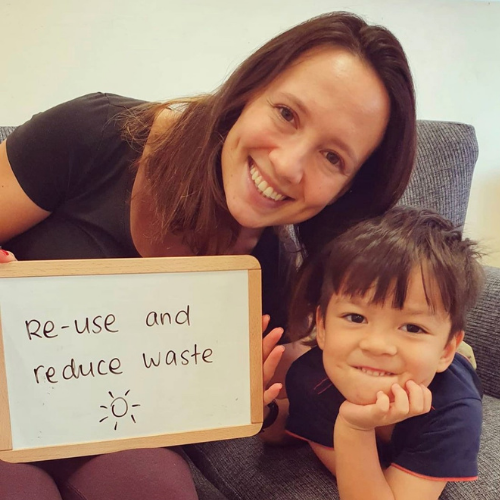

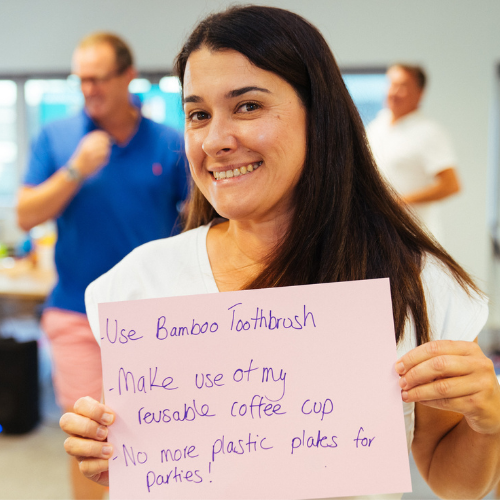

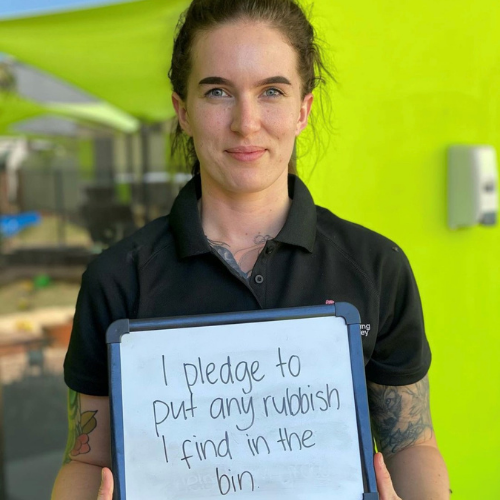

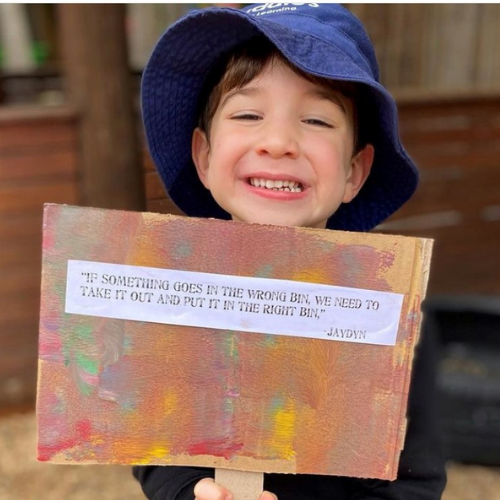

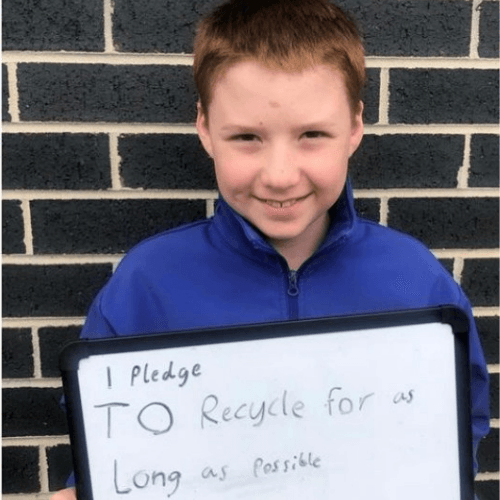

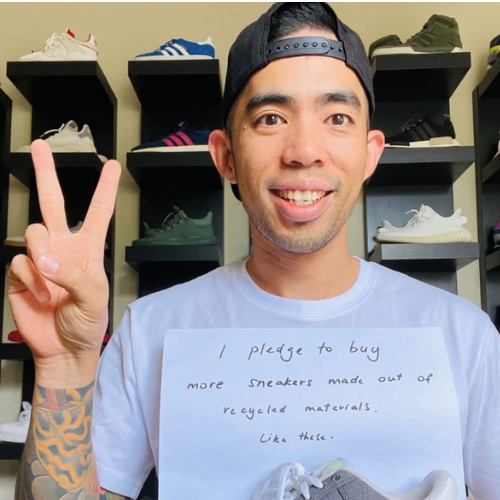

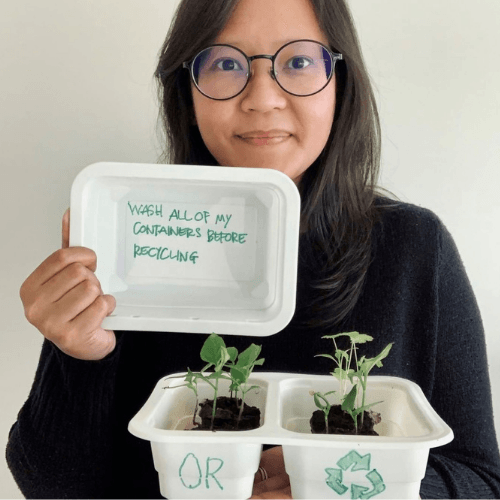

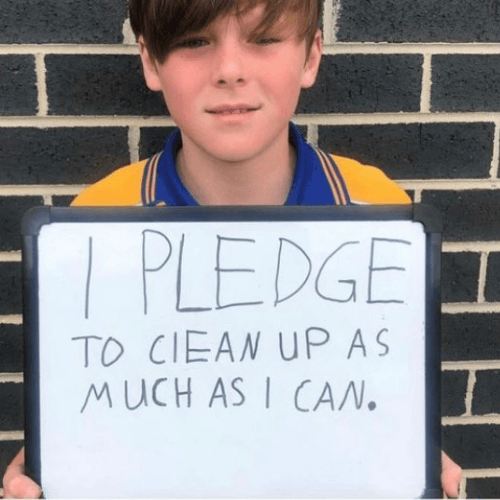

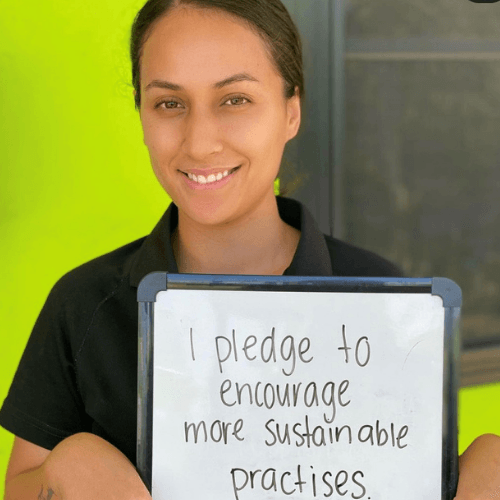

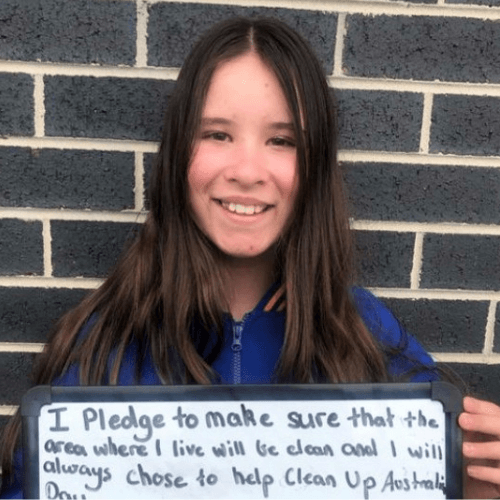

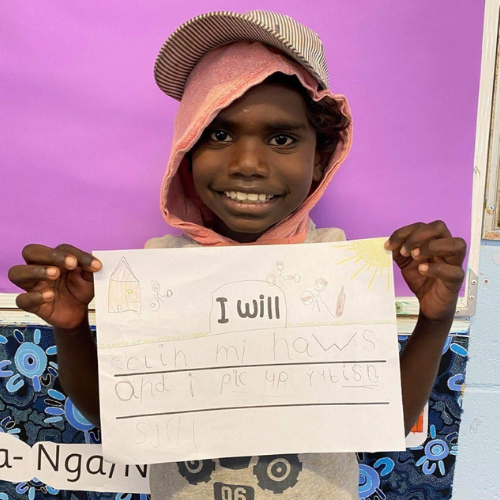

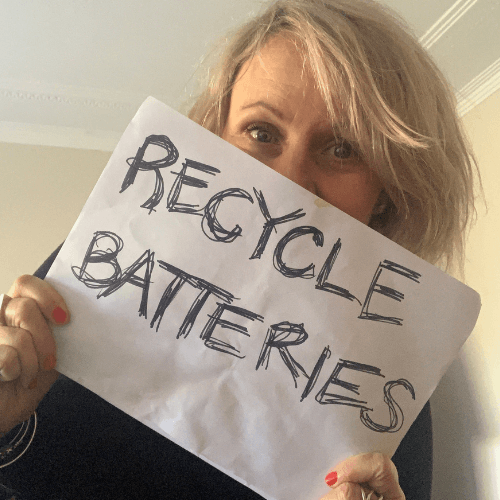

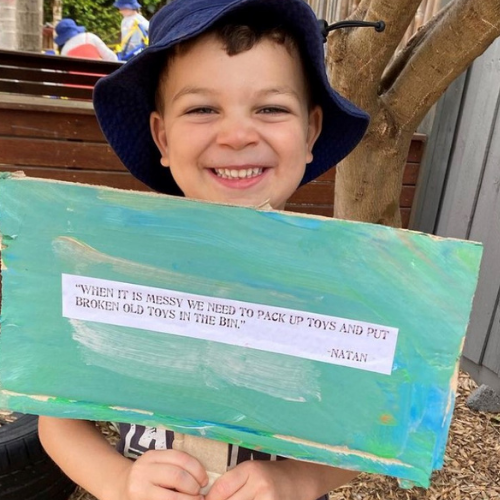

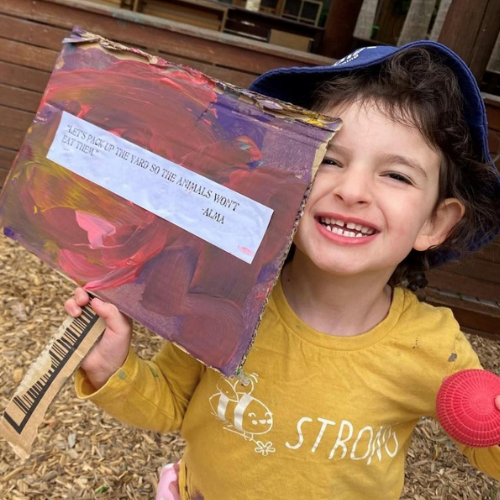

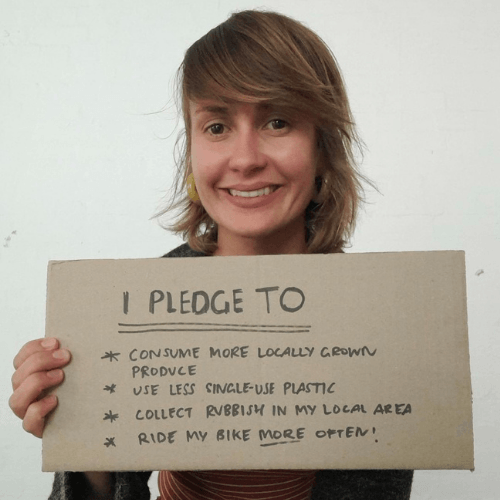

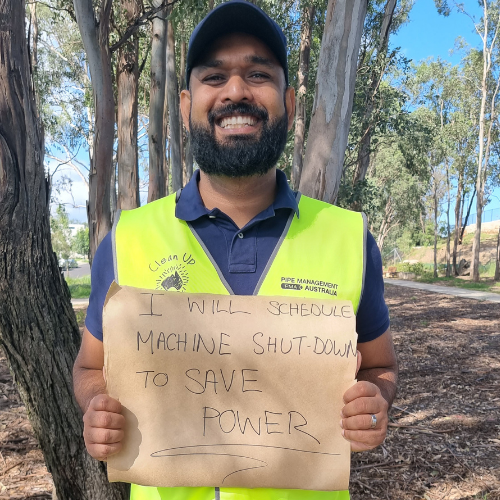

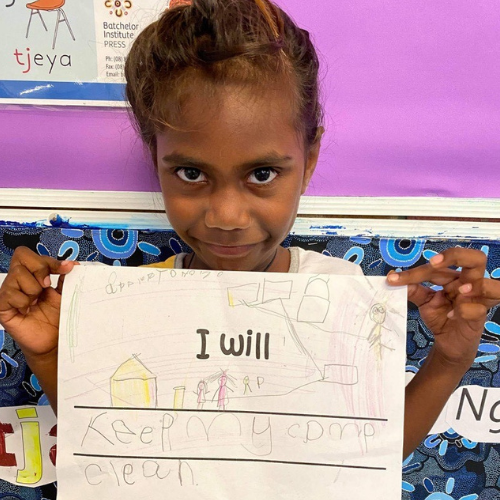

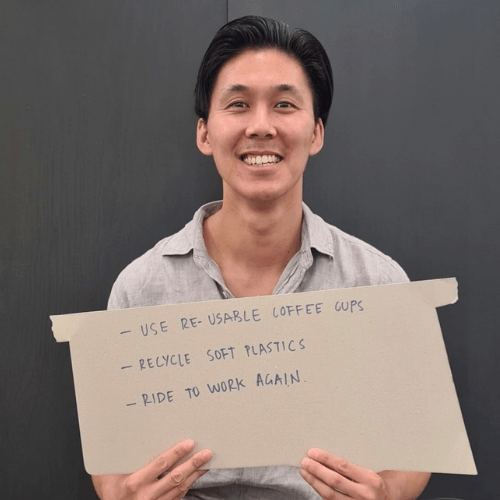

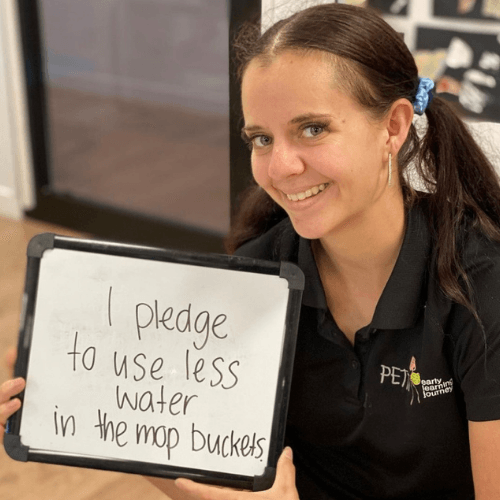

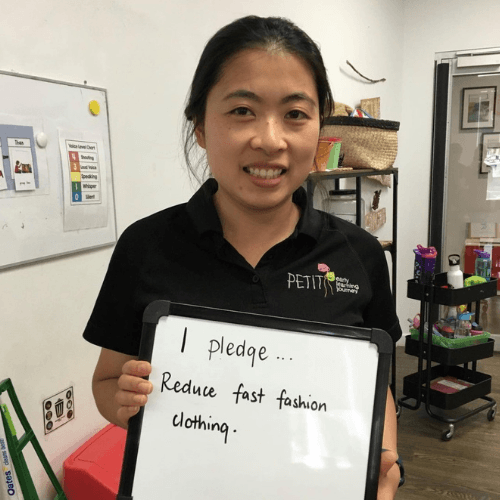

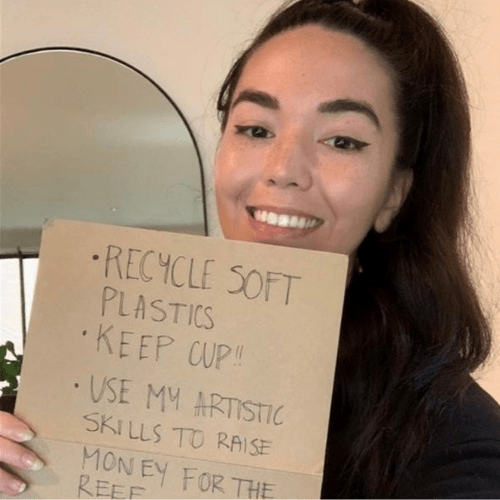

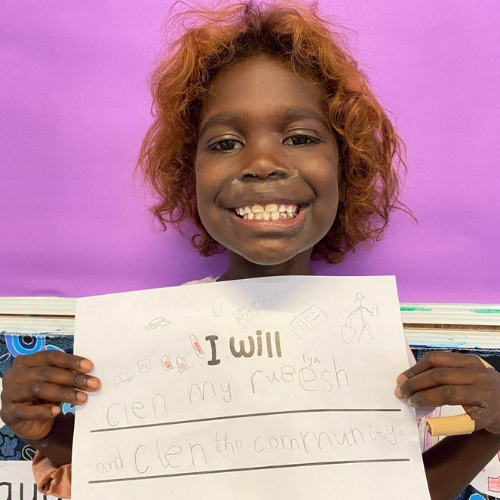

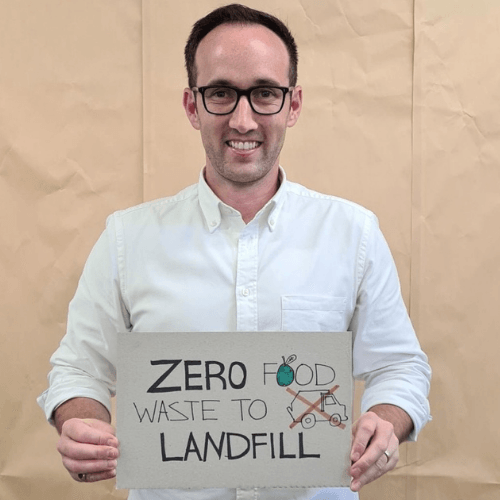

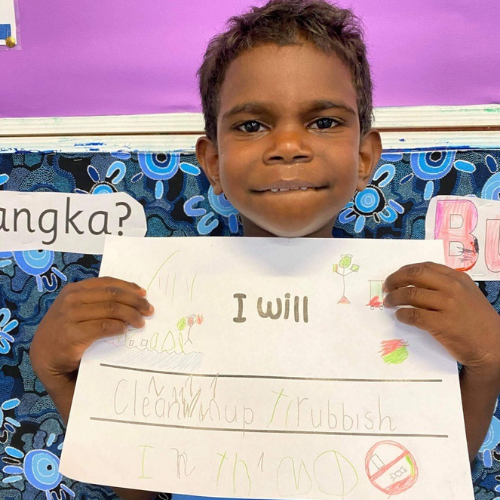

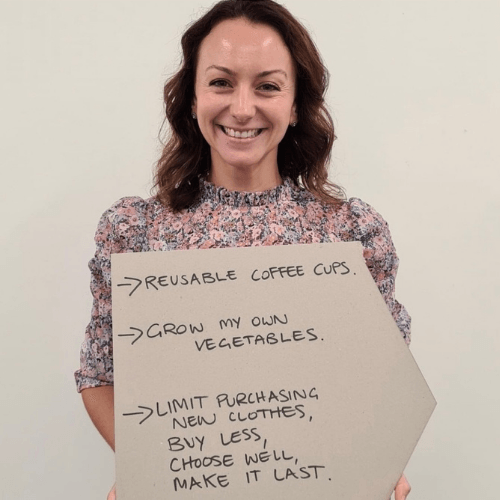

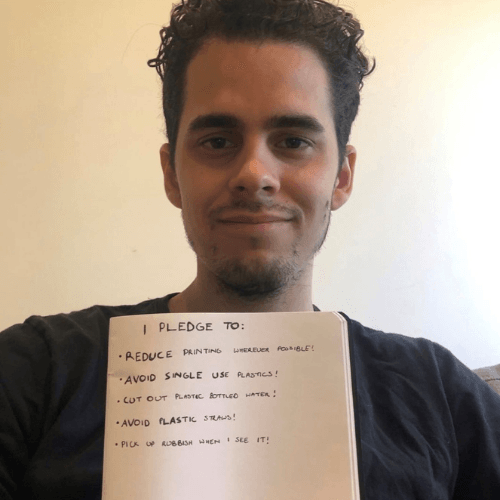

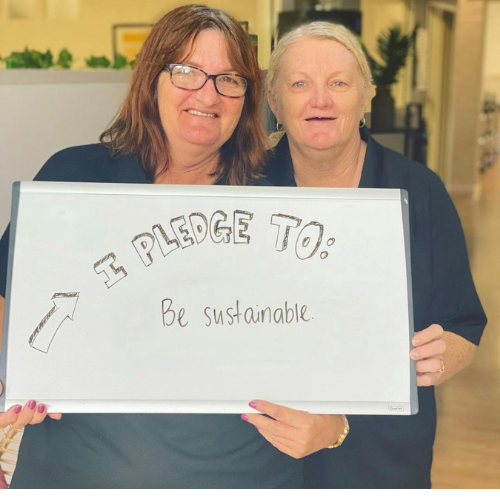

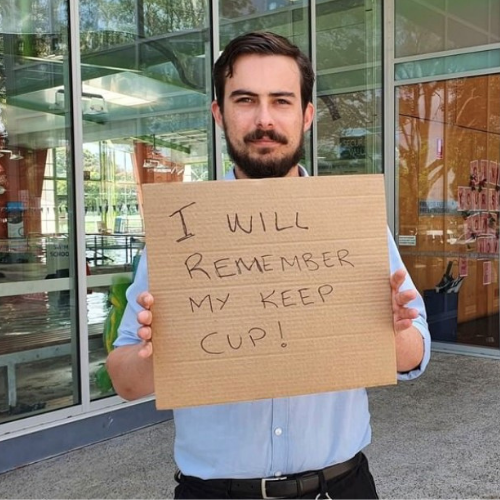

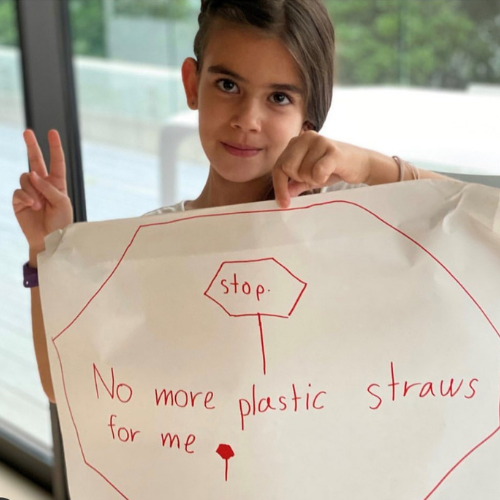

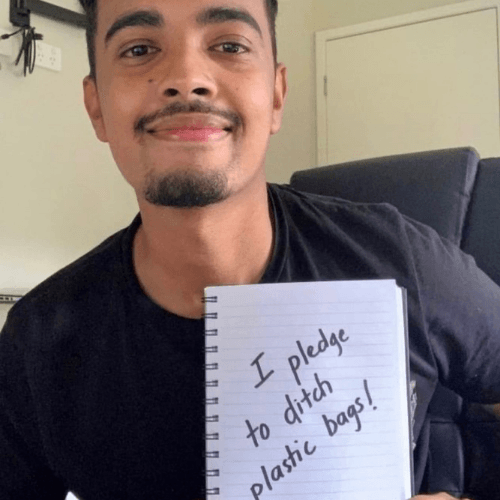

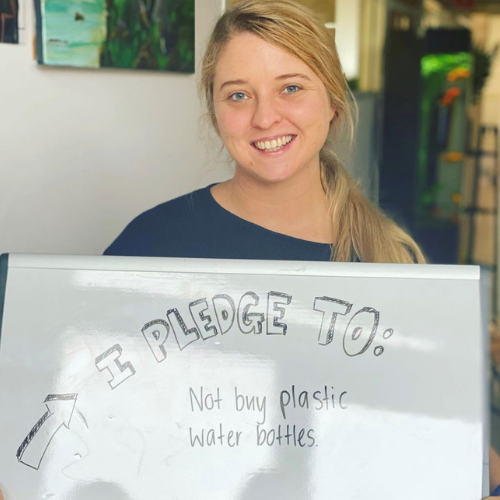

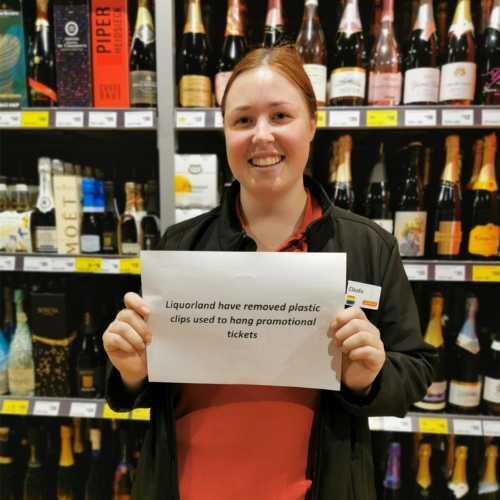

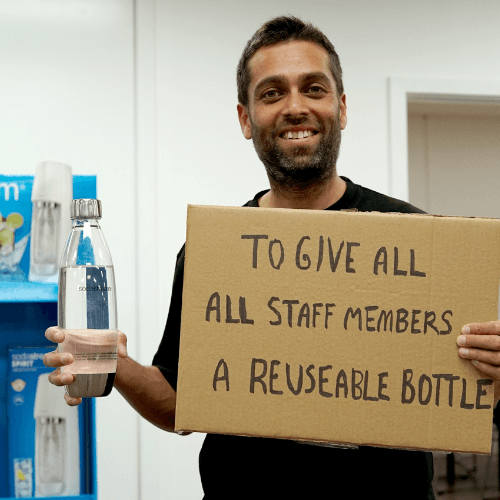

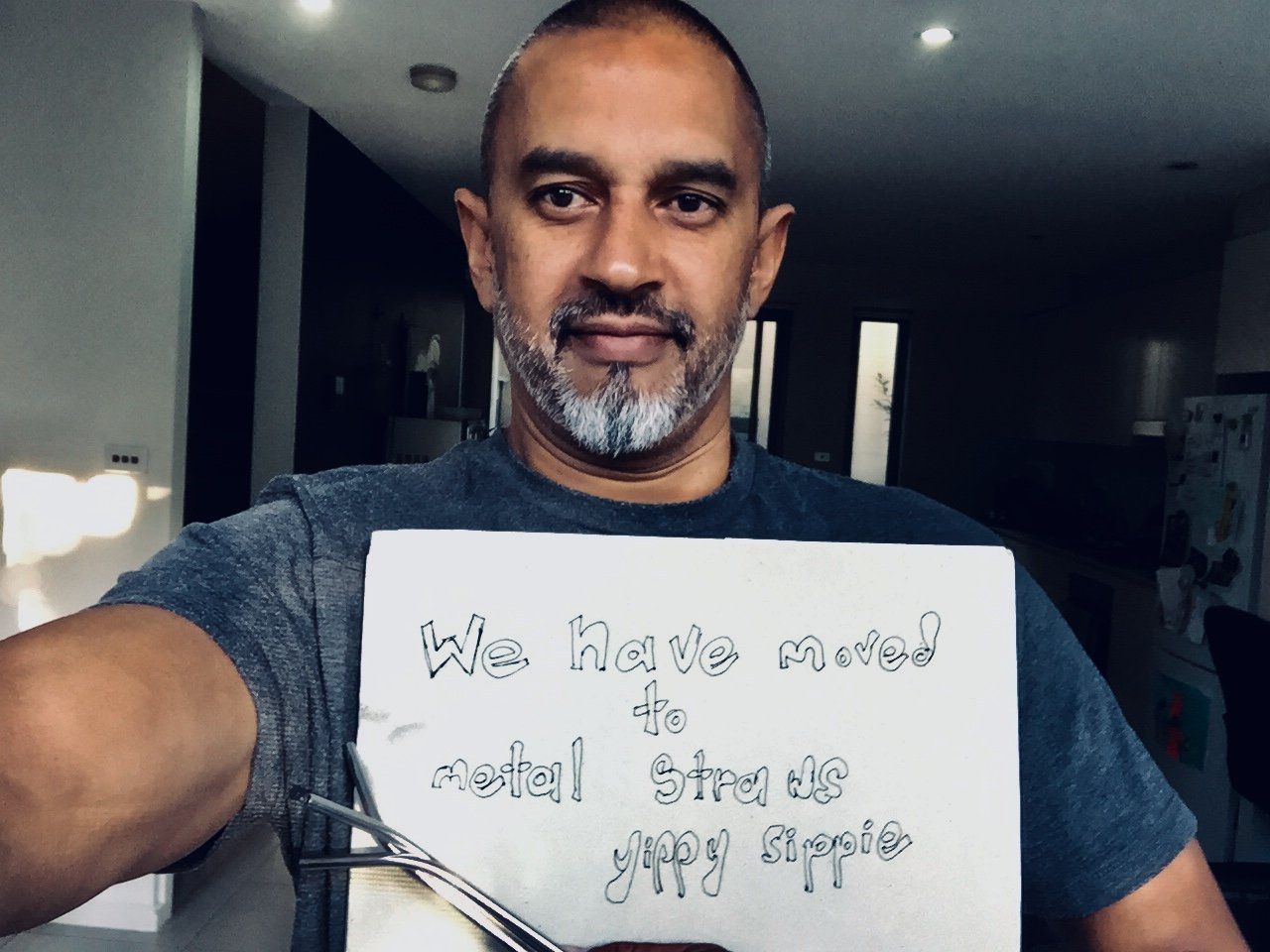

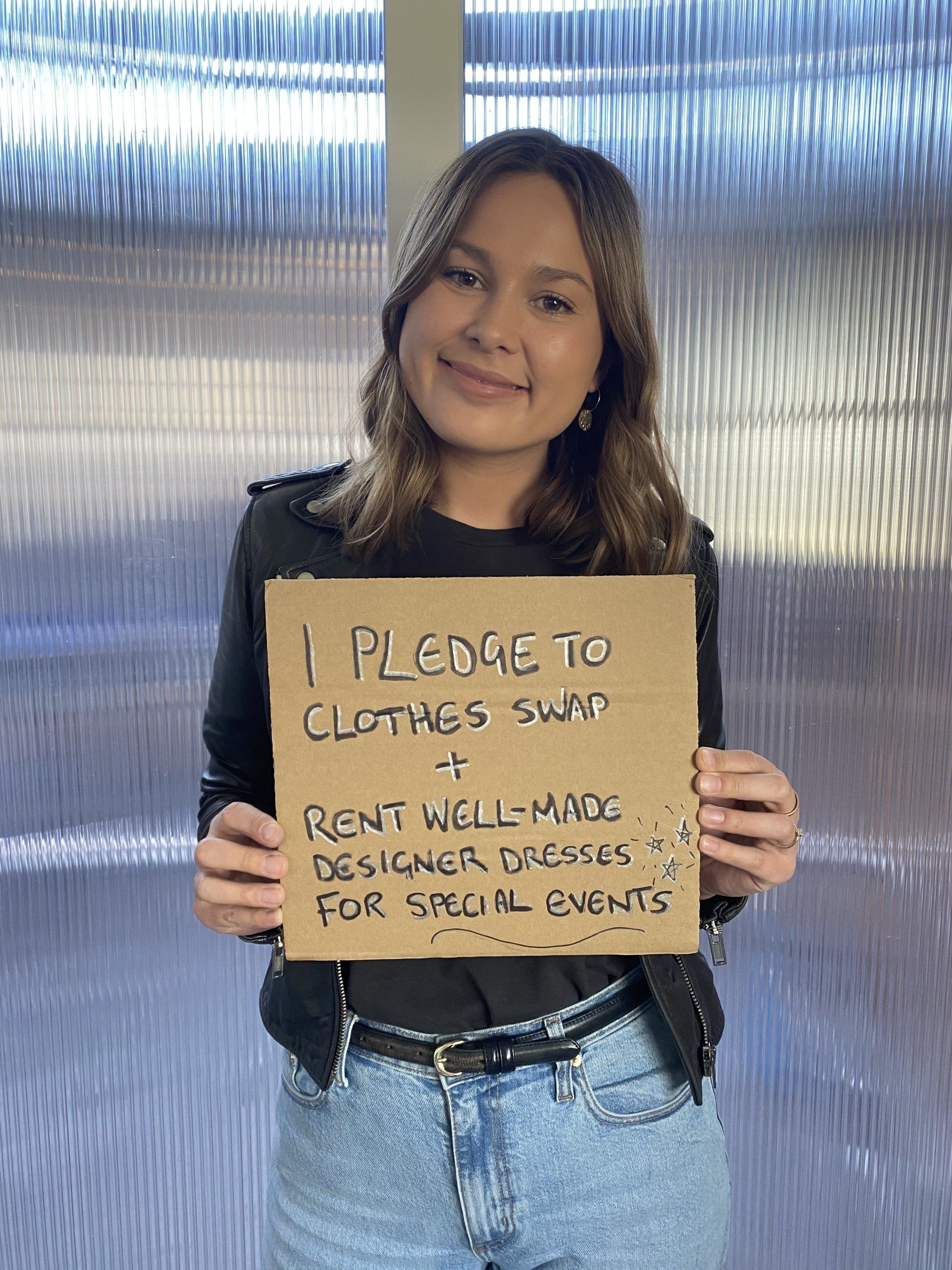

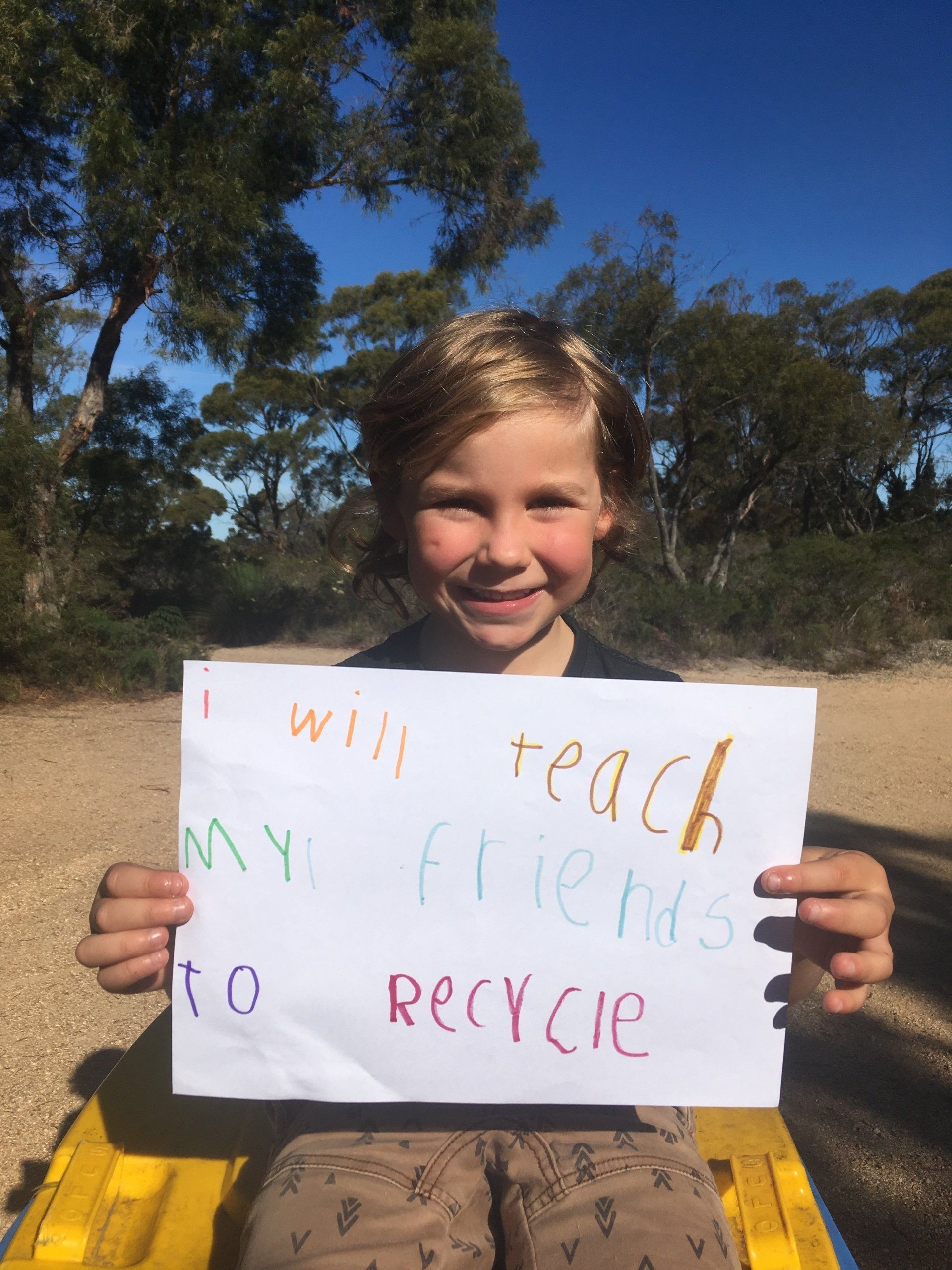

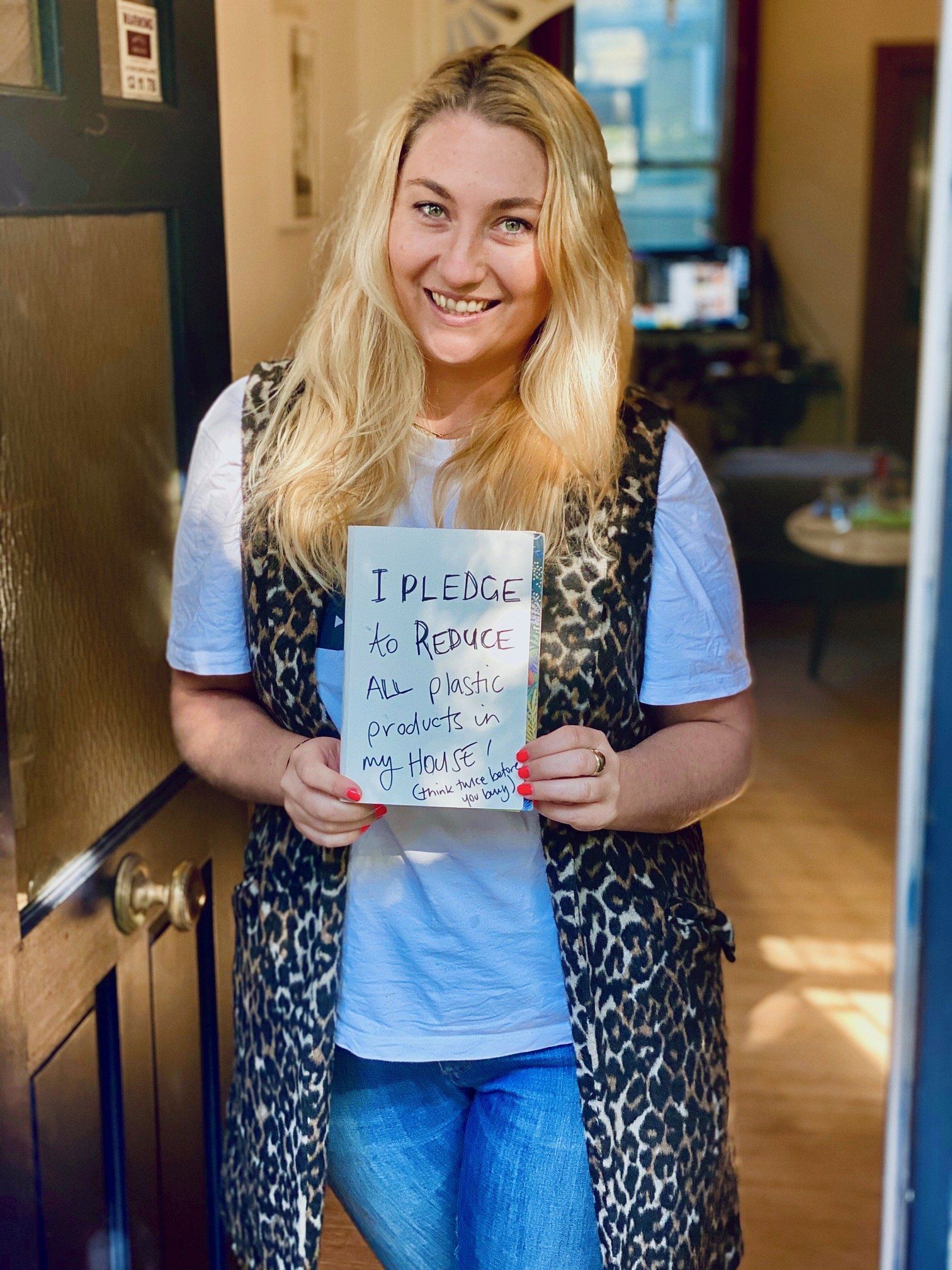

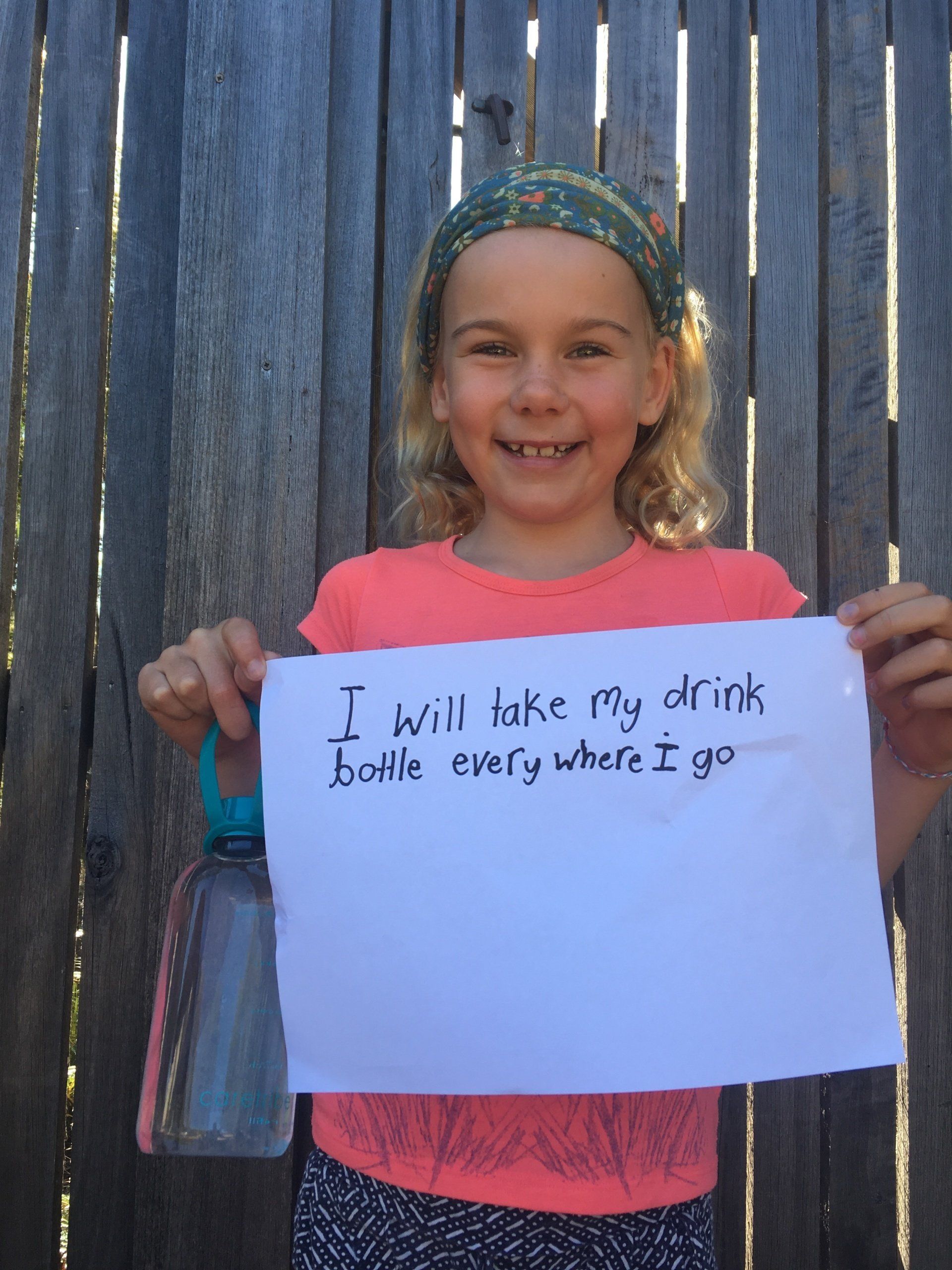

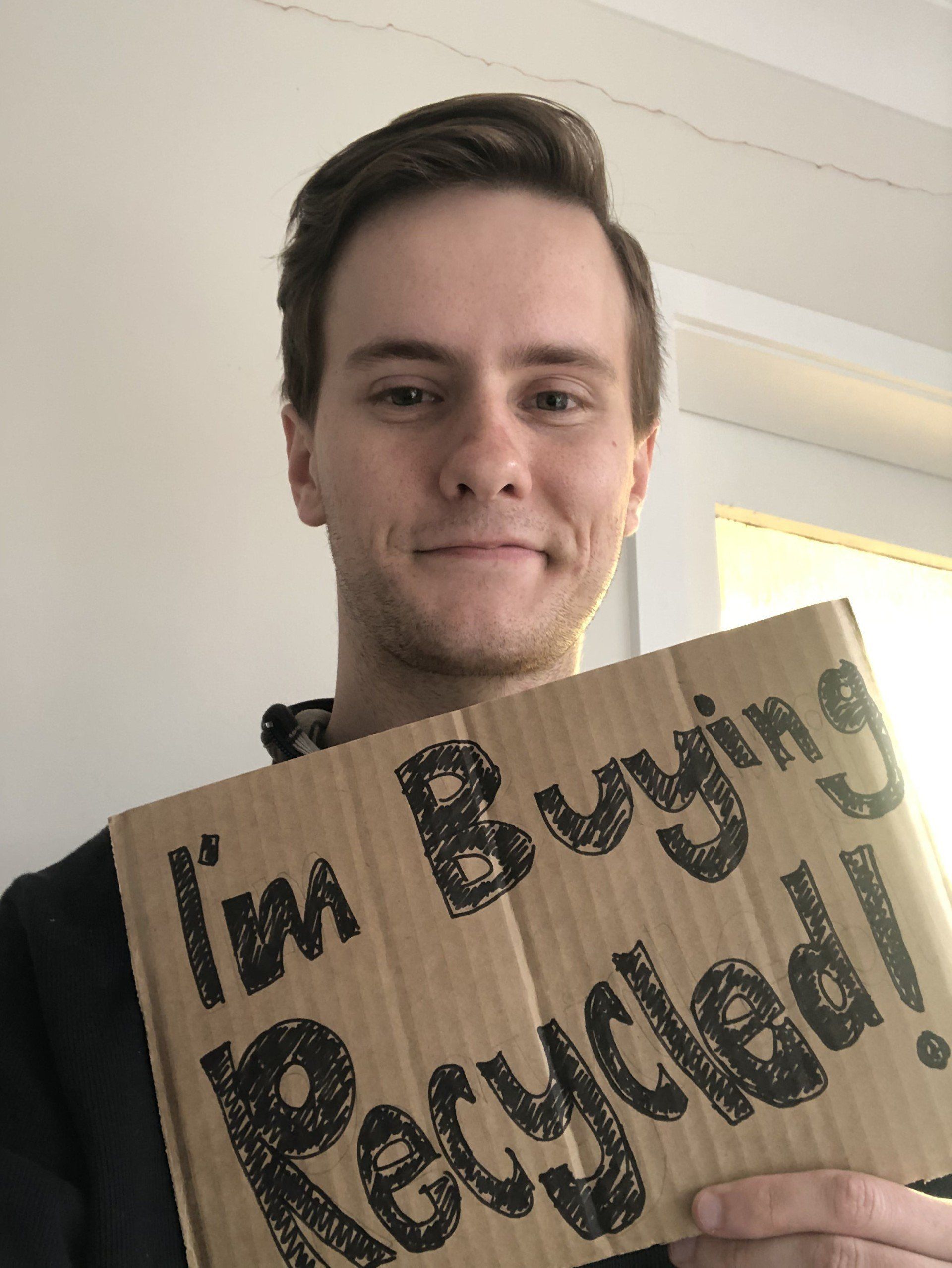

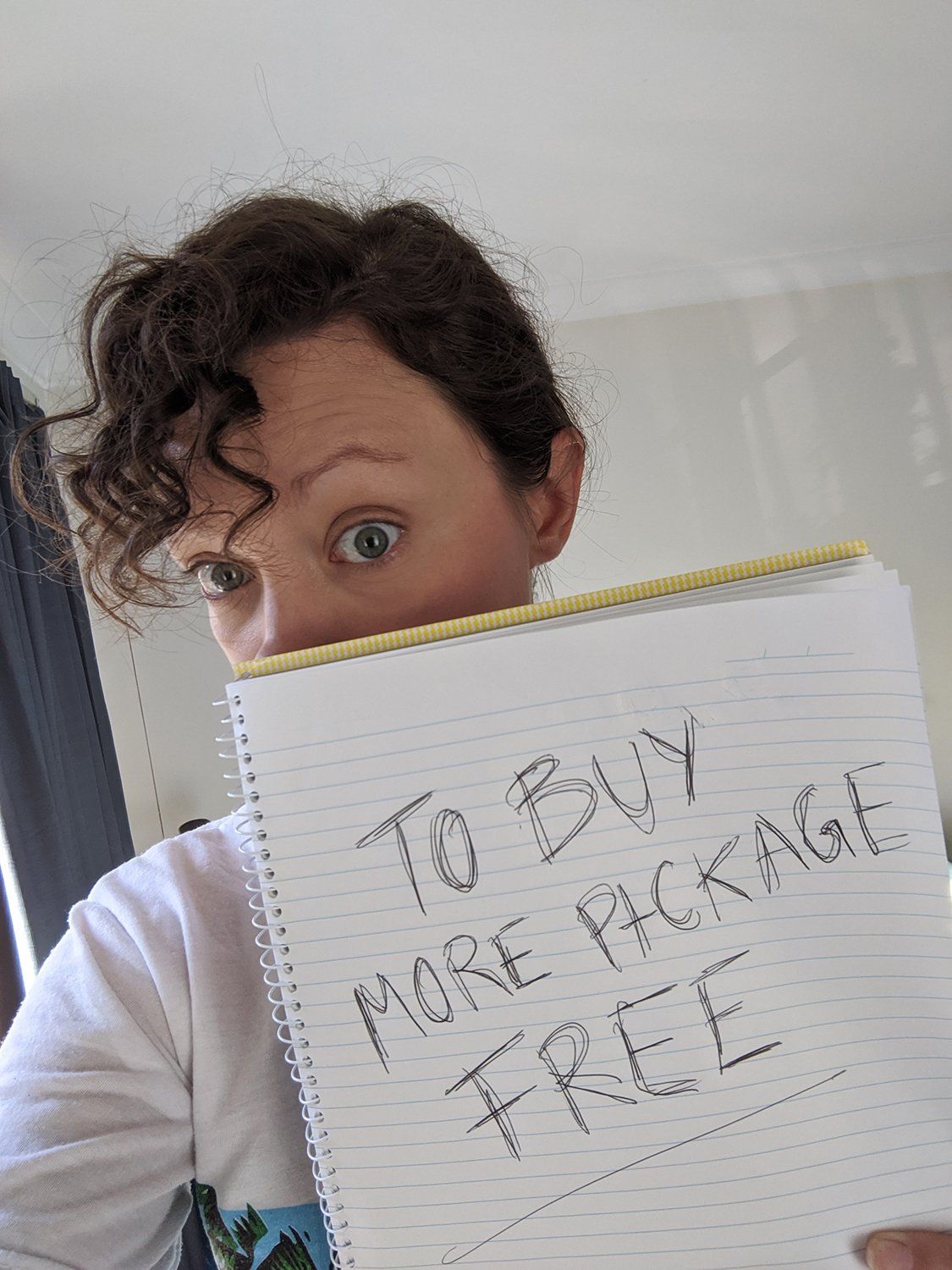

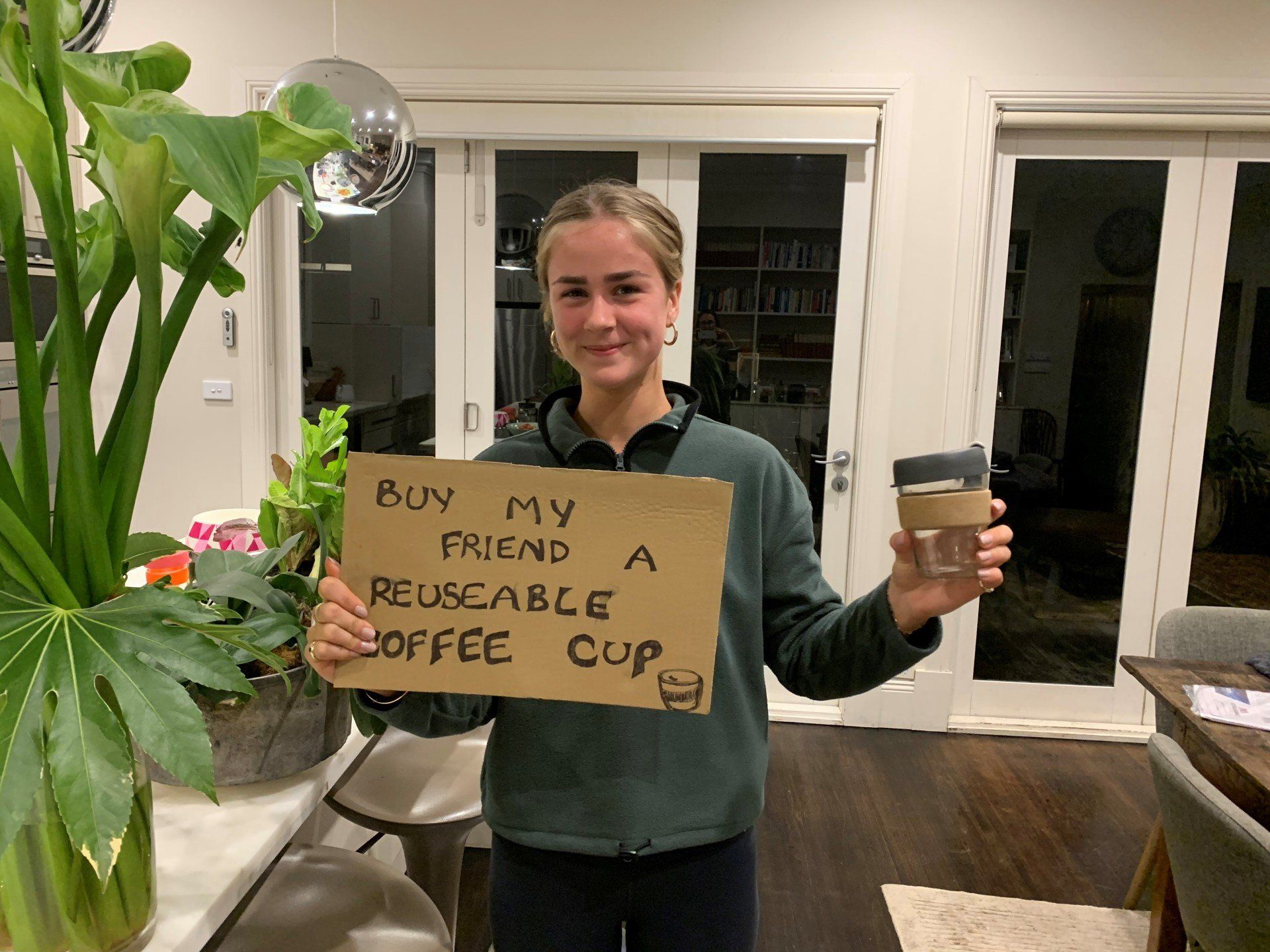

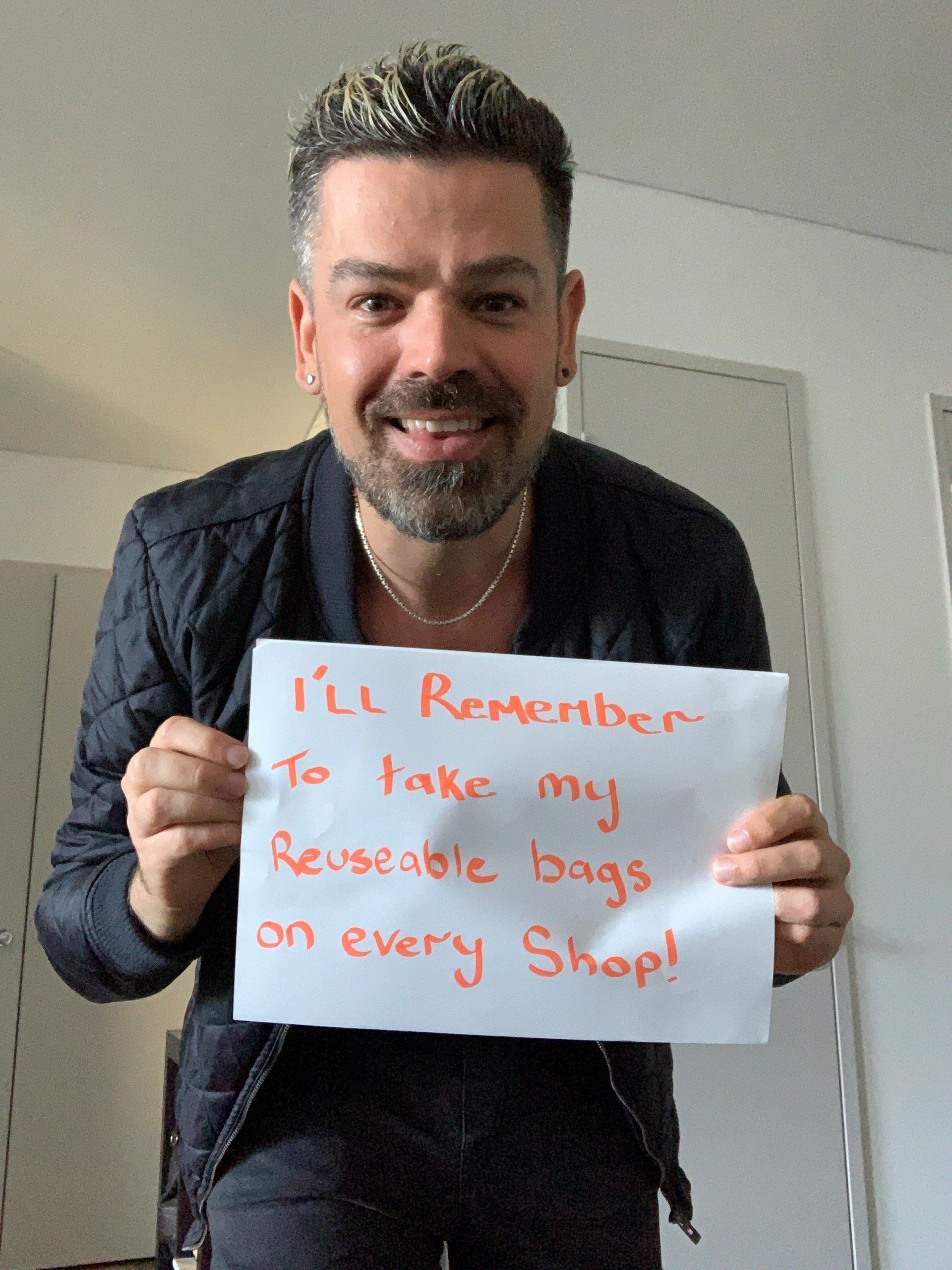

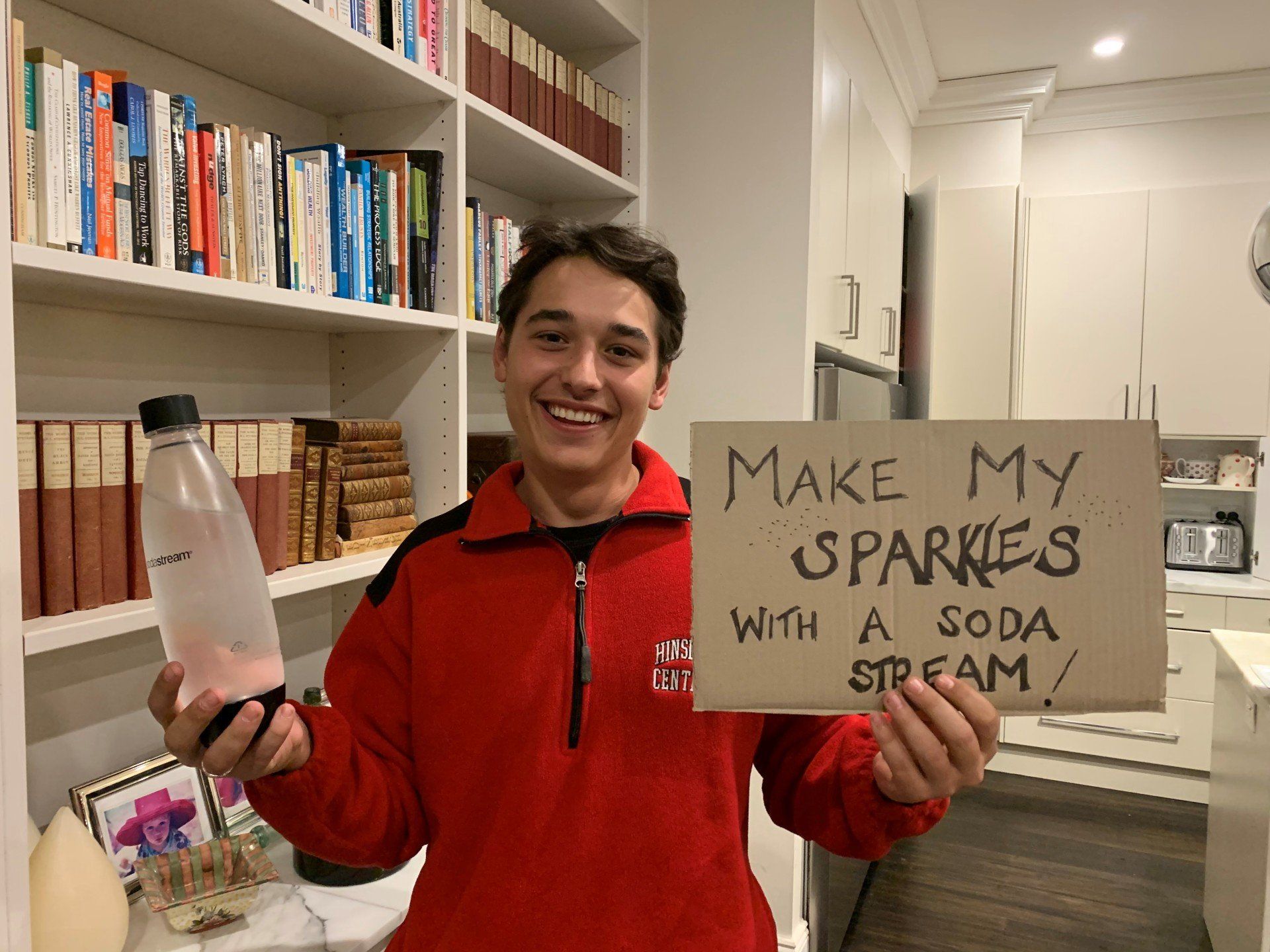

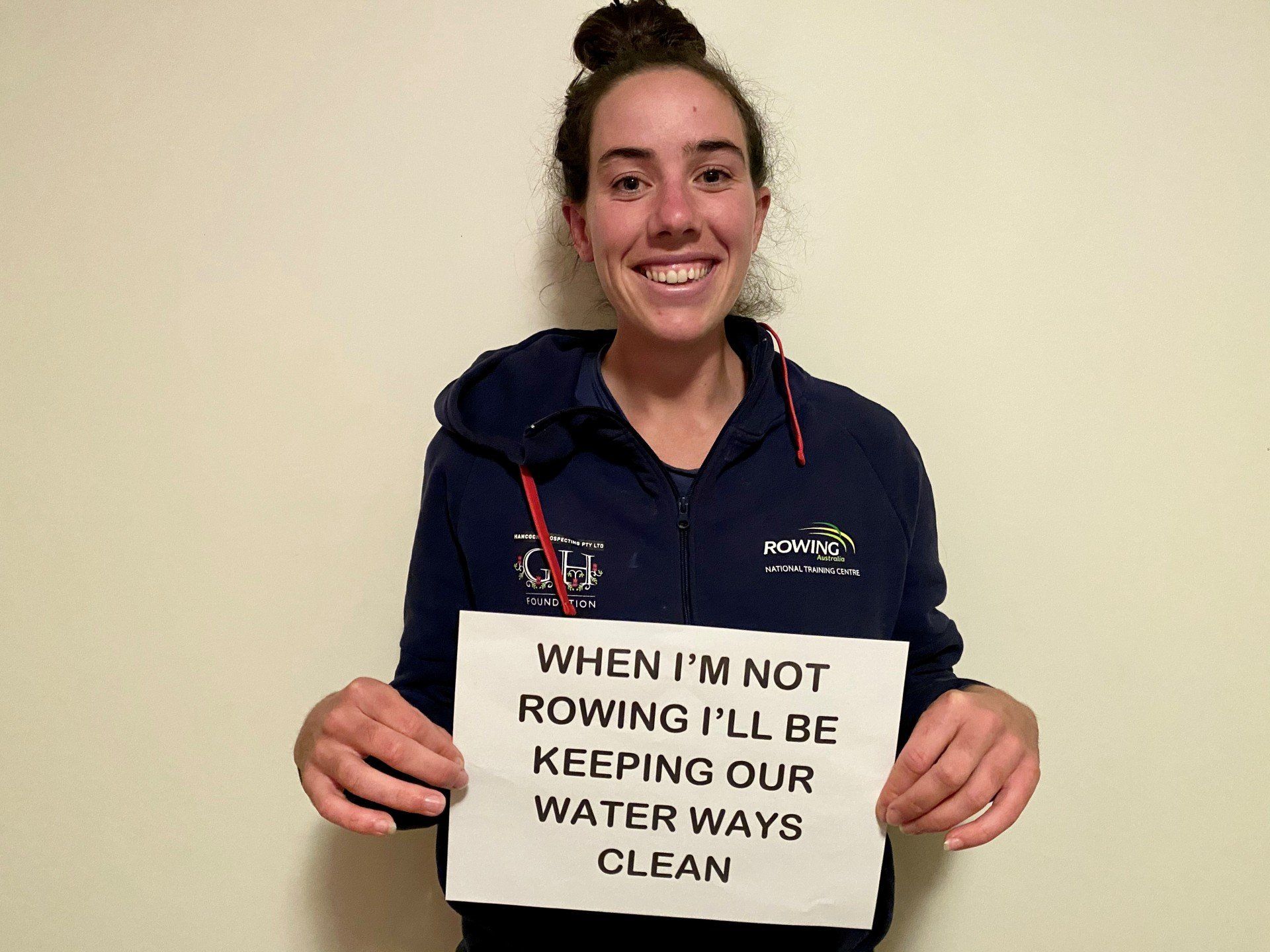

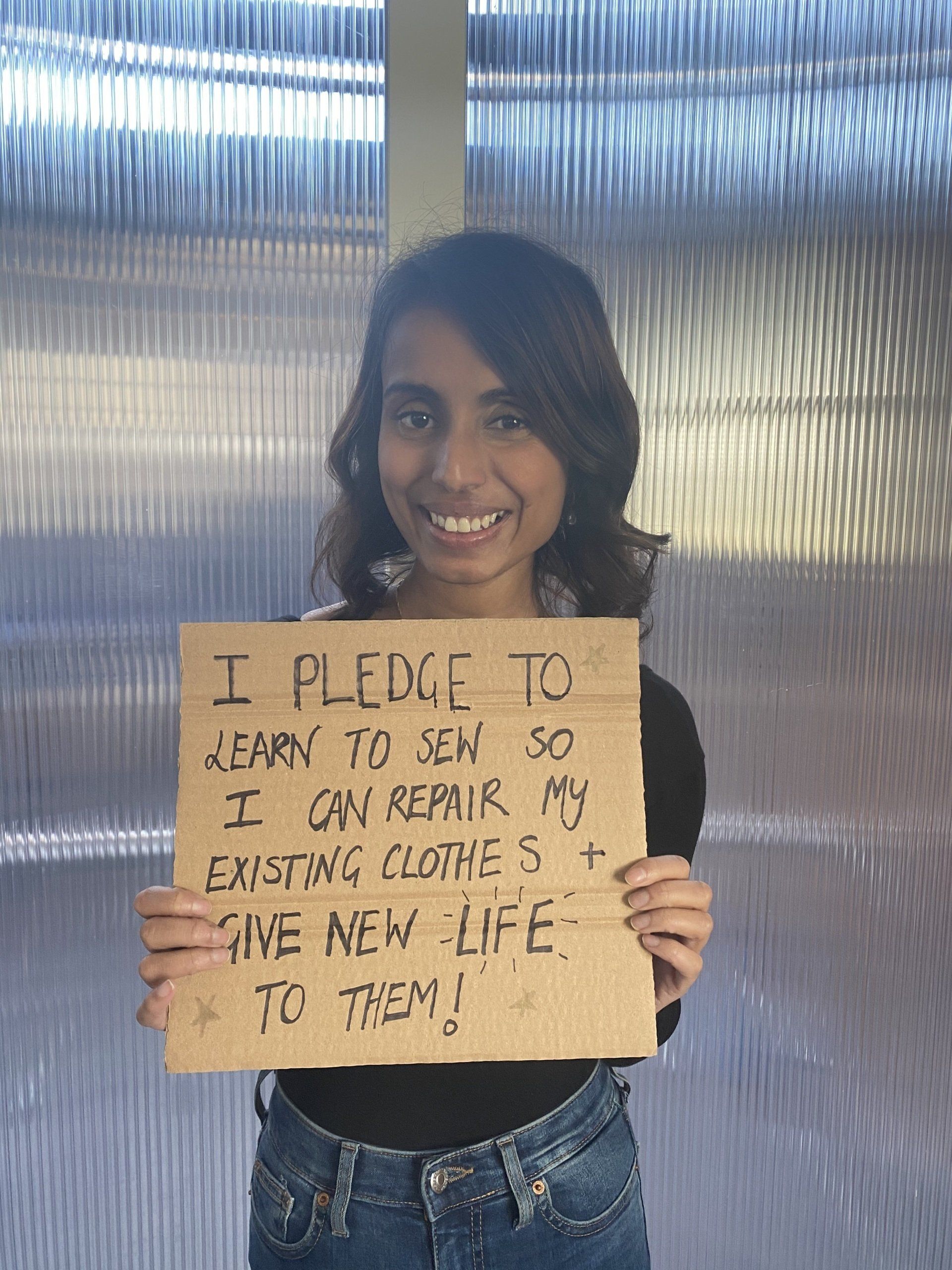

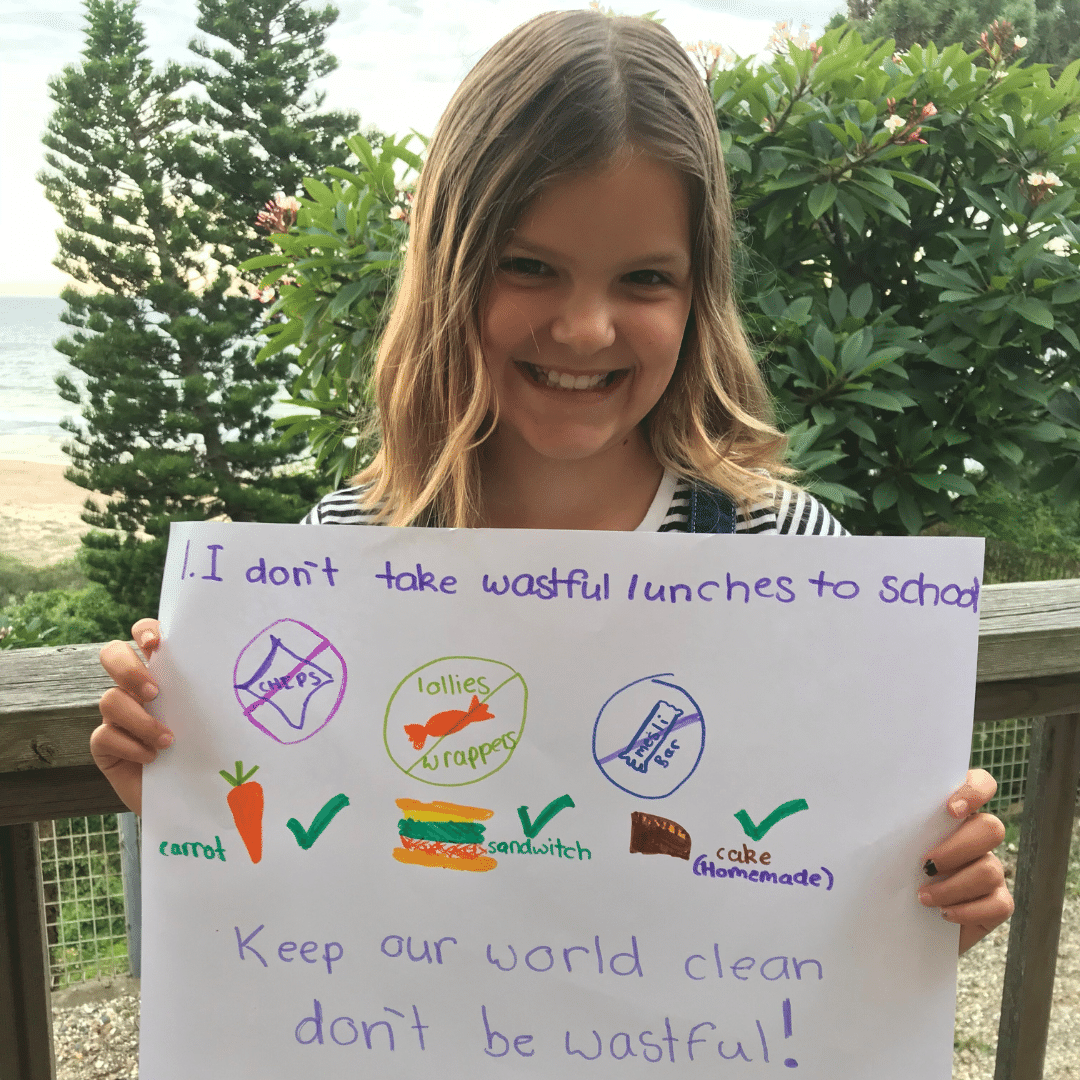

Inspire your family and friends to make a change by sharing your pledge and tagging @CleanUpAustralia #CleanUpAustralia

Clean Up Australia

Clean Up Australia acknowledges the Traditional Owners of Country throughout Australia and their continuing connection to land, waters and community. We pay our respects to Elders past and present.